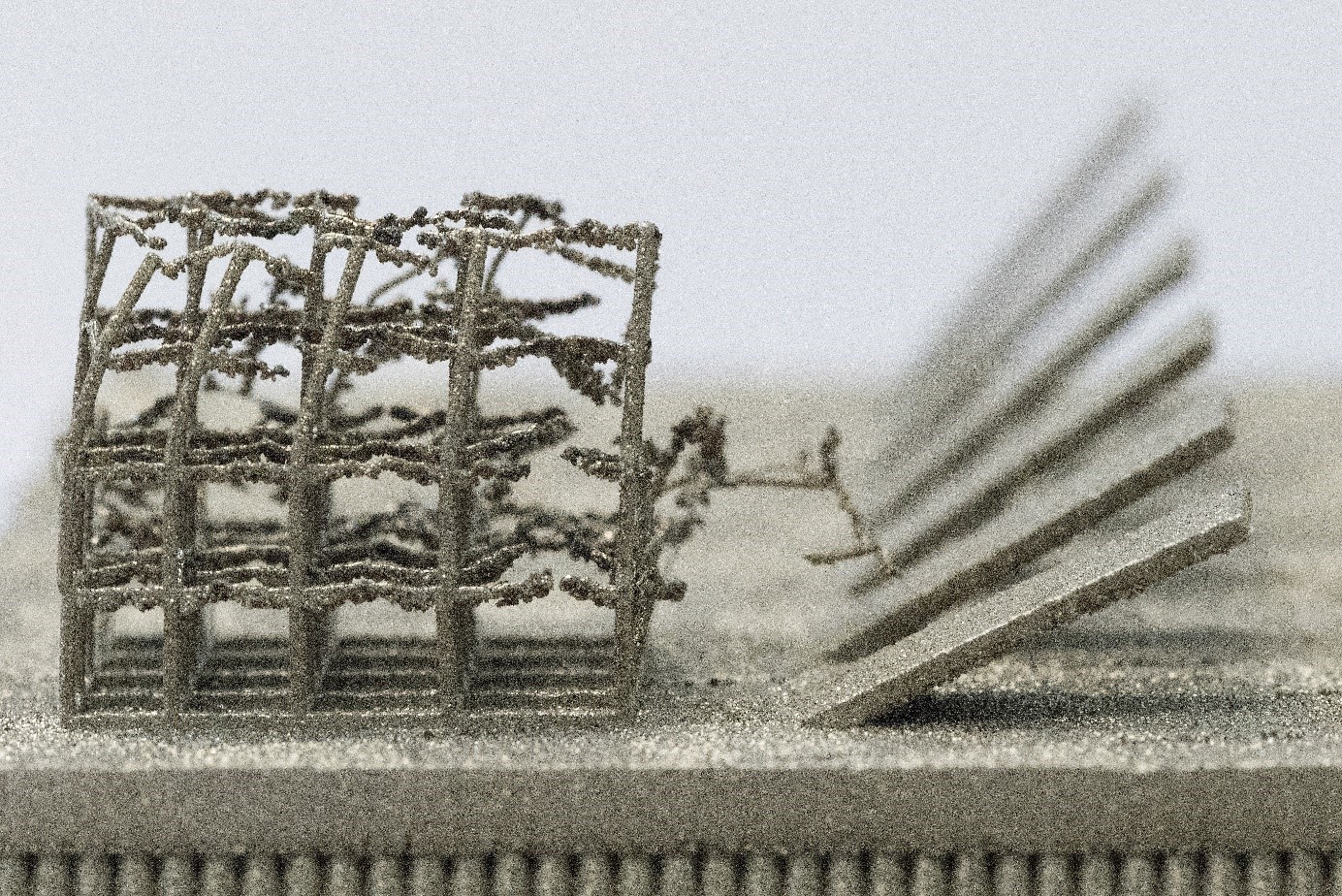

Wire Arc Additive Manufacturing (WAAM) is a technique that allows 3D printing by means of a welding torch on a robotic arm and specialized process settings. The technology has great potential and is therefore seen as a Key Enabeling Technology (KET). The aim of the research is to improve acquisition processes for Wire Arc AdditiveContinue reading “Selection method for WAAM”

Category Archives: Project

Biz 1

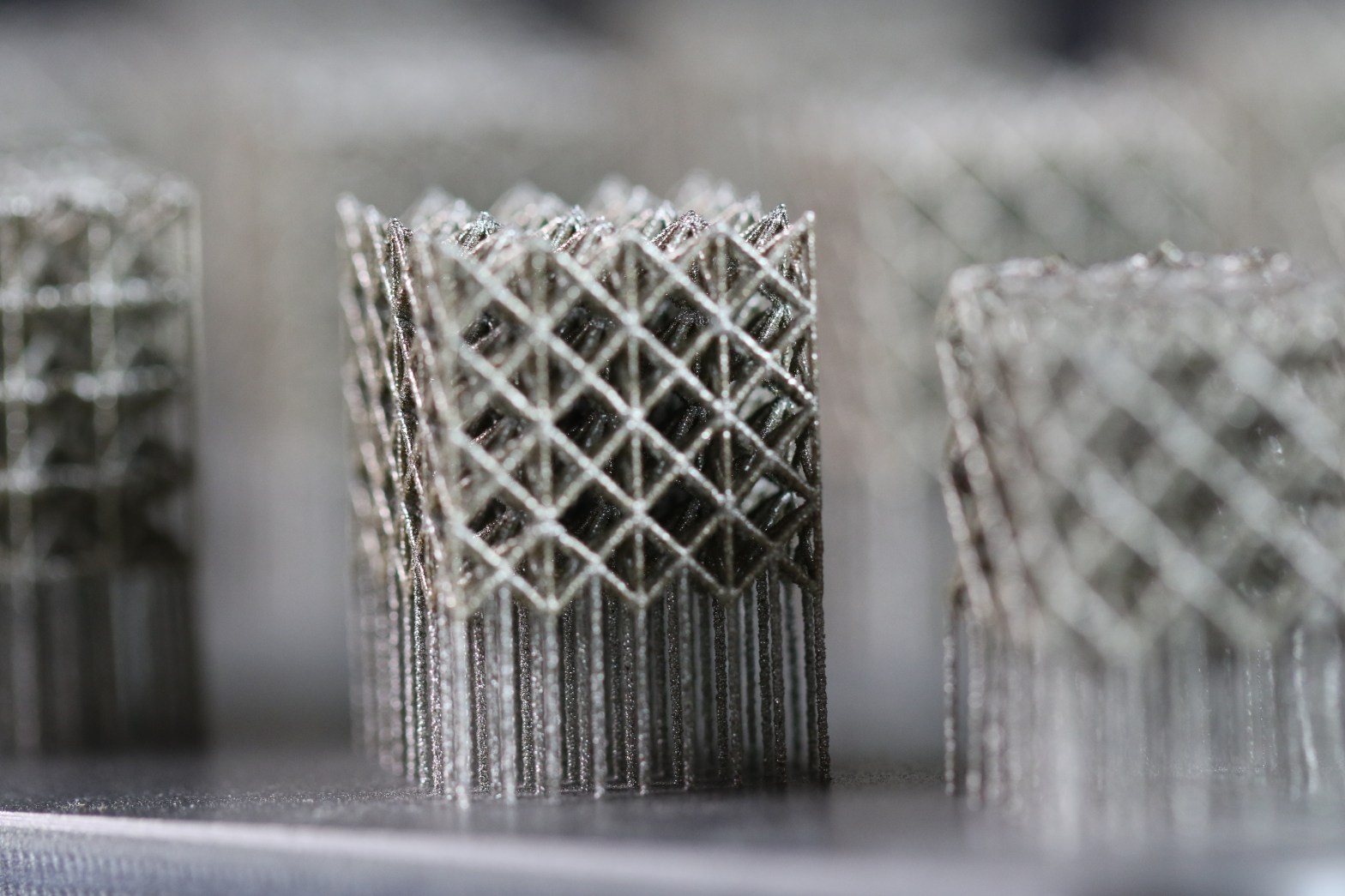

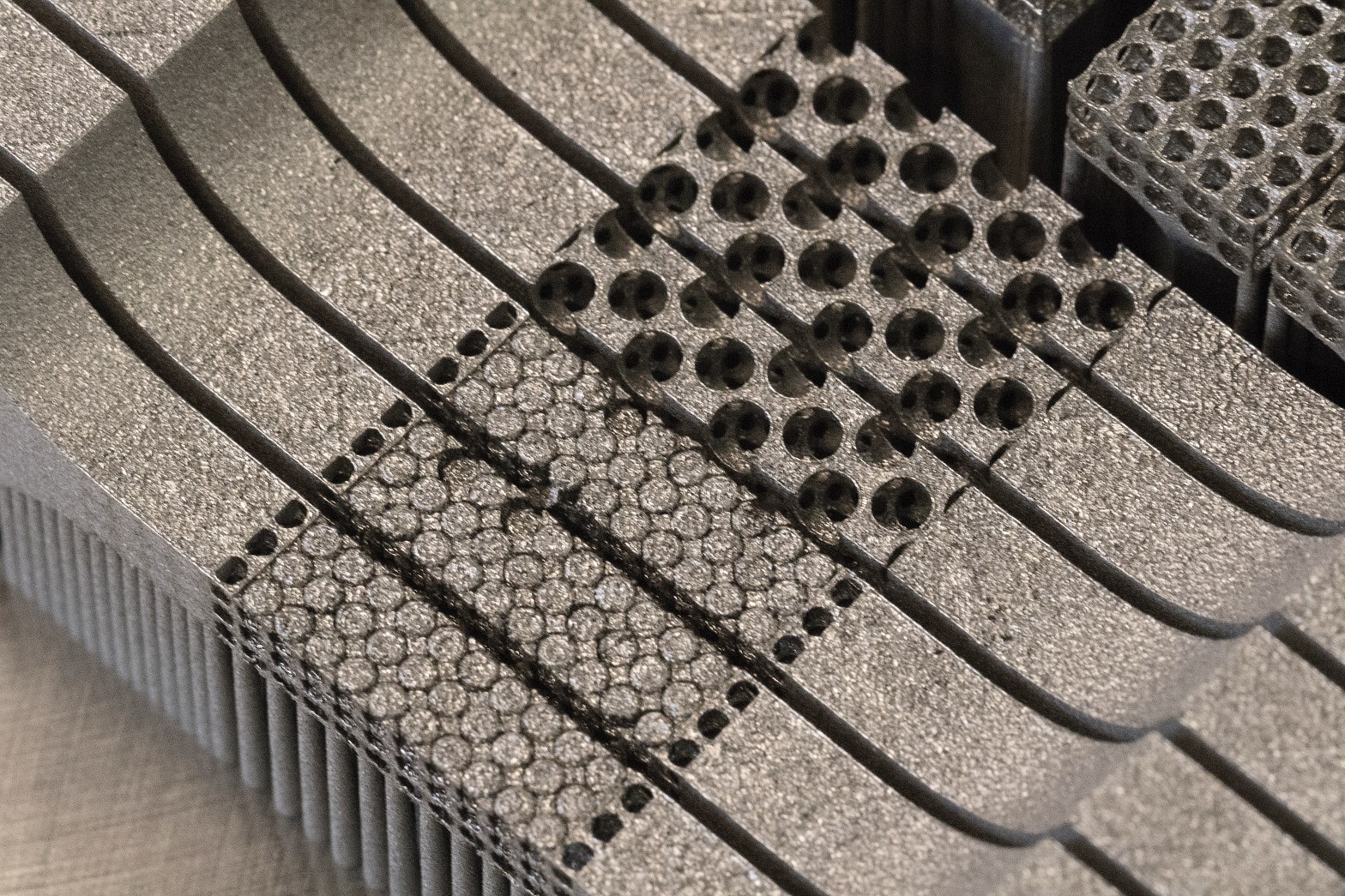

Exploration of the possibilities of 3D metal printing. What possibilities and limitations does 3D metal printing have as a production technique? What new challenges does this present for designers? 3D printing requires a different approach to the design process. The research group Industrial Design has composed design guidelines for this. Business economic aspects have alsoContinue reading “Biz 1”

Biz 2

Establishing design and production guidelines. Together with 5 regional partners; Thales, Z-tech, AWL, PM-Aerotec and Aeronamic a research project has been set up for the development and anchoring of knowledge about 3D metal printing. This is done by means of specific questions coming from the companies through generic technical research and developments of future-proof specificContinue reading “Biz 2”

Spare parts

Developing a 3D repair cycle in which old or broken parts are scanned or measured, digitally repaired, 3D-printed and reworked, until they are ready for use. 3D printing technology (Additive Manufacturing, AM for short) has undergone strong development over the past 10 years, with special applications. Plastic is a well-known 3D printing material, and newContinue reading “Spare parts”