3D metal print at Saxion

Applied research into 3D metal printing

Projects

Biz 1

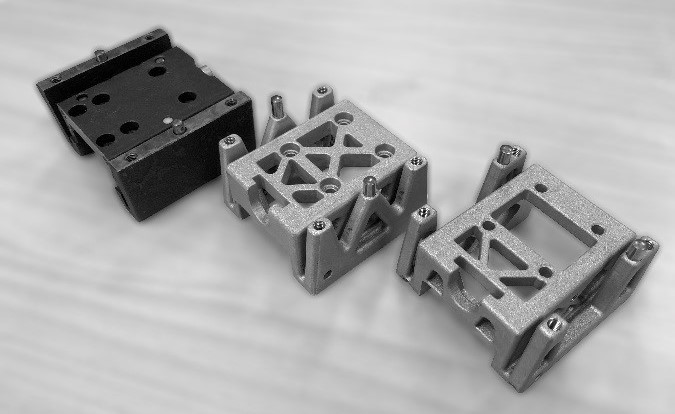

Exploration of the possibilities of 3D metal printing. What possibilities and limitations does 3D metal printing have as a production technique? What new challenges does this present for designers? 3D printing requires a different approach to the design process. The research group Industrial Design has composed design guidelines for this. Business economic aspects have also…

Biz 2

Establishing design and production guidelines. Together with 5 regional partners; Thales, Z-tech, AWL, PM-Aerotec and Aeronamic a research project has been set up for the development and anchoring of knowledge about 3D metal printing. This is done by means of specific questions coming from the companies through generic technical research and developments of future-proof specific…

Spare parts

Developing a 3D repair cycle in which old or broken parts are scanned or measured, digitally repaired, 3D-printed and reworked, until they are ready for use. 3D printing technology (Additive Manufacturing, AM for short) has undergone strong development over the past 10 years, with special applications. Plastic is a well-known 3D printing material, and new…

Selection method for WAAM

Wire Arc Additive Manufacturing (WAAM) is a technique that allows 3D printing by means of a welding torch on a robotic arm and specialized process settings. The technology has great potential and is therefore seen as a Key Enabeling Technology (KET). The aim of the research is to improve acquisition processes for Wire Arc Additive…

Research approach

A hands-on approach in solving current issues from the industry. We use applied reseach methodologies to investigate challenging questions and unveal innovative solutions. At us, technological possibilities are integrated to answer people’s or company needs. We pioneer user-centered solutions through different ways of thinking and new technologies. All research is done in collaboration with Small-Medium Enterprises (SME’s). Typically applied research is conducted in higher Technology Readiness Levels (TRLs), starting from 5 up to 8 (and sometimes even 9).

Team Lectoraat Industrial Design

Our team members come from diverse academic and commercial background ensuring creative and practical approach to projects.

Professor Industrial Product Design: Karin van Beurden

Project leader: Ivo Vrooijink

Researchers: Wouter Weijermars, Paul Groneveld,

Ernst-Jan Goedvolk, Erik Goselink, Iman Hadzhivalcheva

Technical coordinator: Sebastiaan Moes

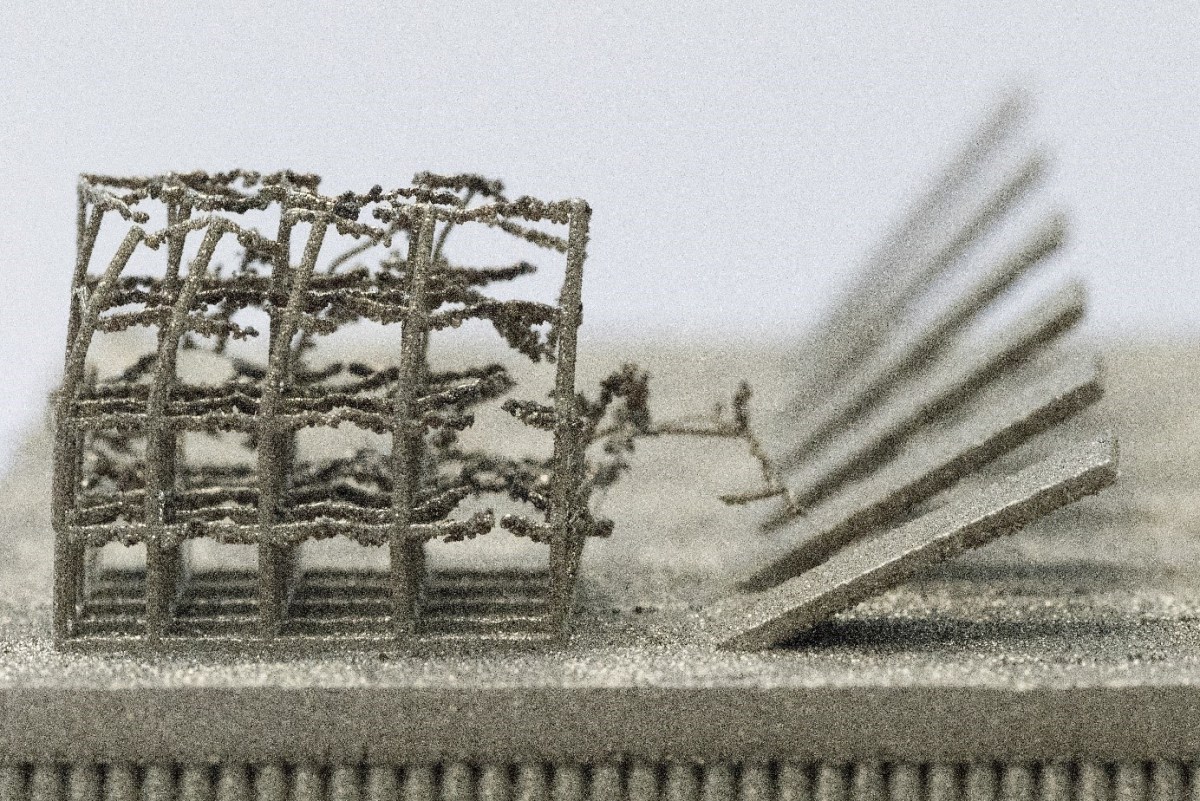

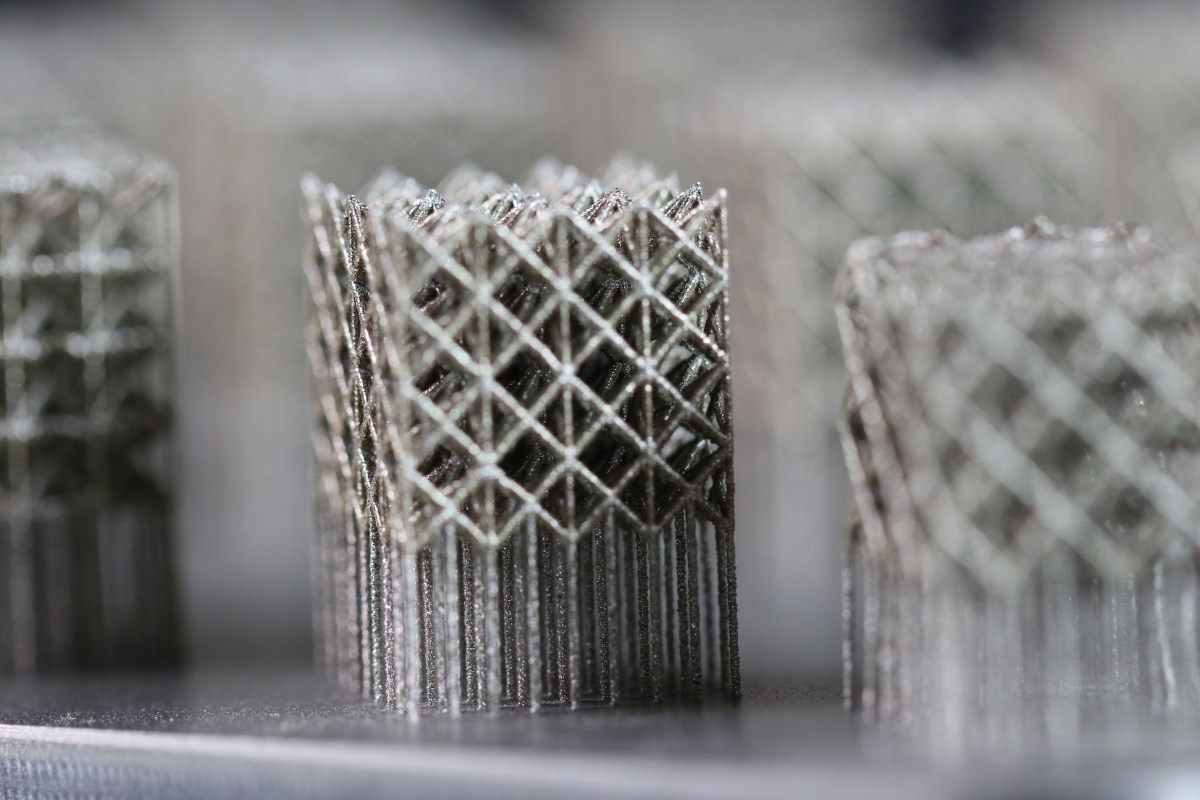

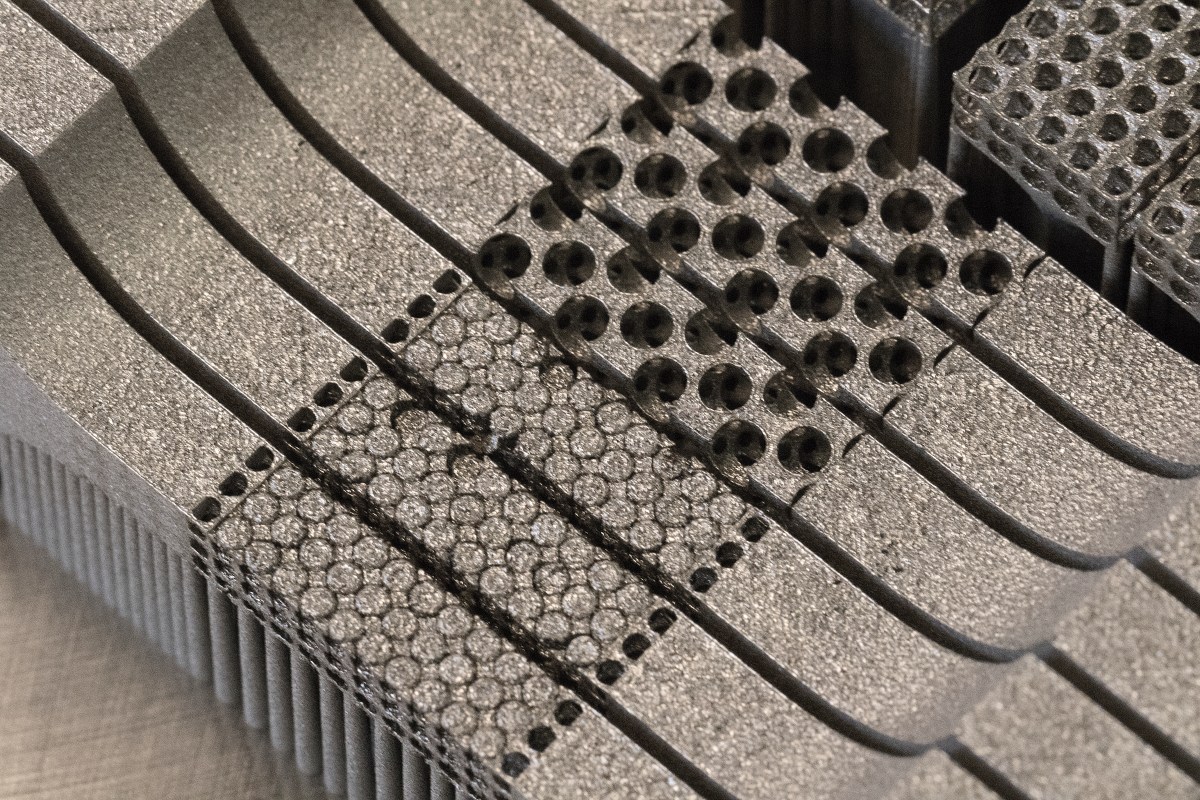

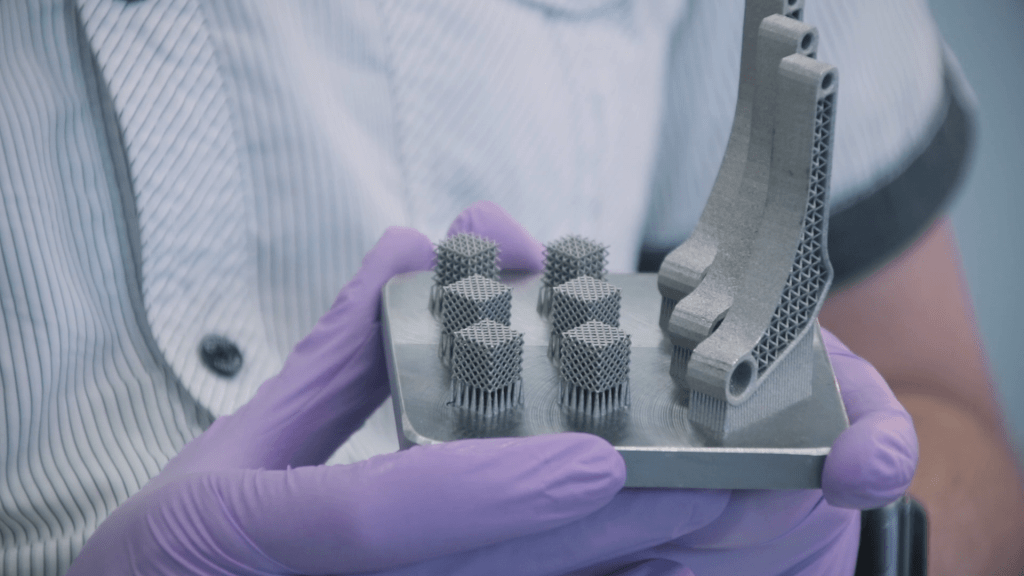

3D Metal Printing Lab

In our 3D metal print lab, the Industrial Design research group is able to research and prototype ideas in a very quick and efficient manner.

Research is being conducted into the It is now easy to adjust structures to your wishes and function and to implement structural and functional optimisation.

Impression

Partners