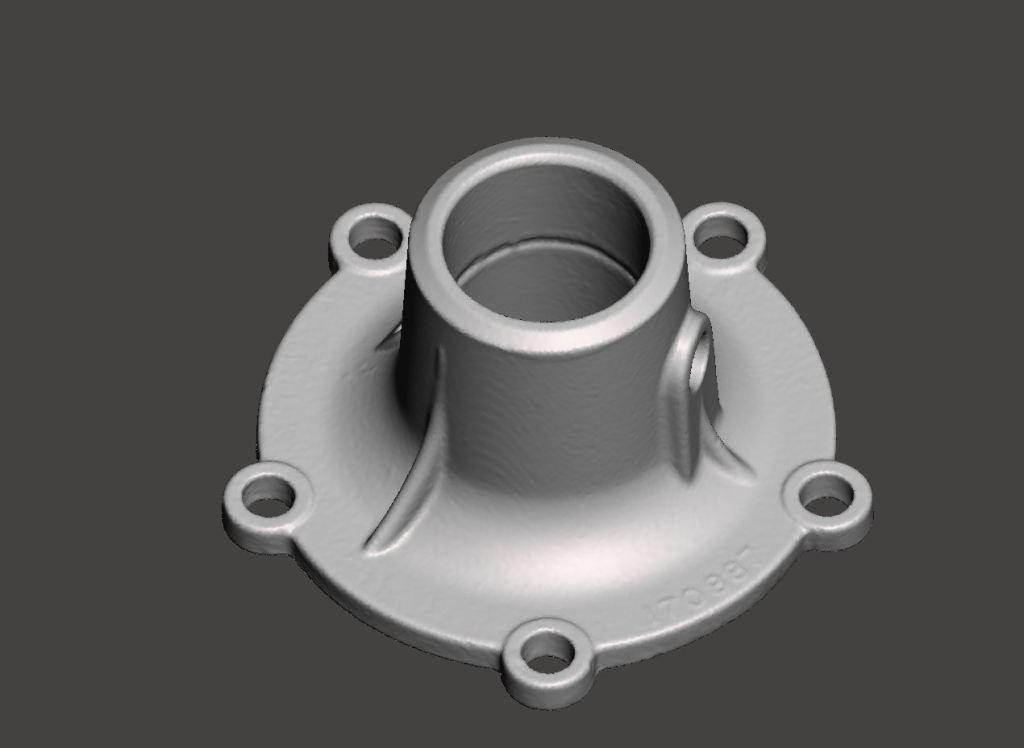

The original waterpump is cast, It is possible to have them reproduced at foundries in Turkey, for example. The disadvantage is that the delivery times are long (8-10 weeks) and no single items can be purchased. This makes single-piece production by means of 3D printing interesting. The intention with this part is to make the spare part as similar as possible to the original. The part was scanned with a 3D scanner from 4C, called the Artec Spider,

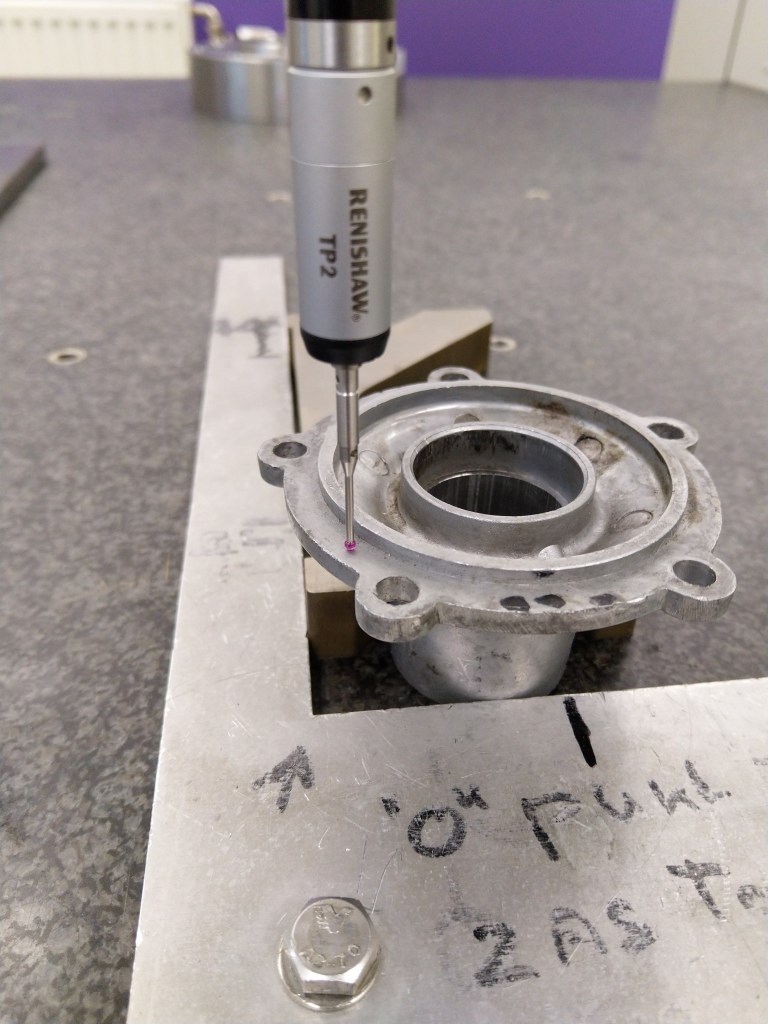

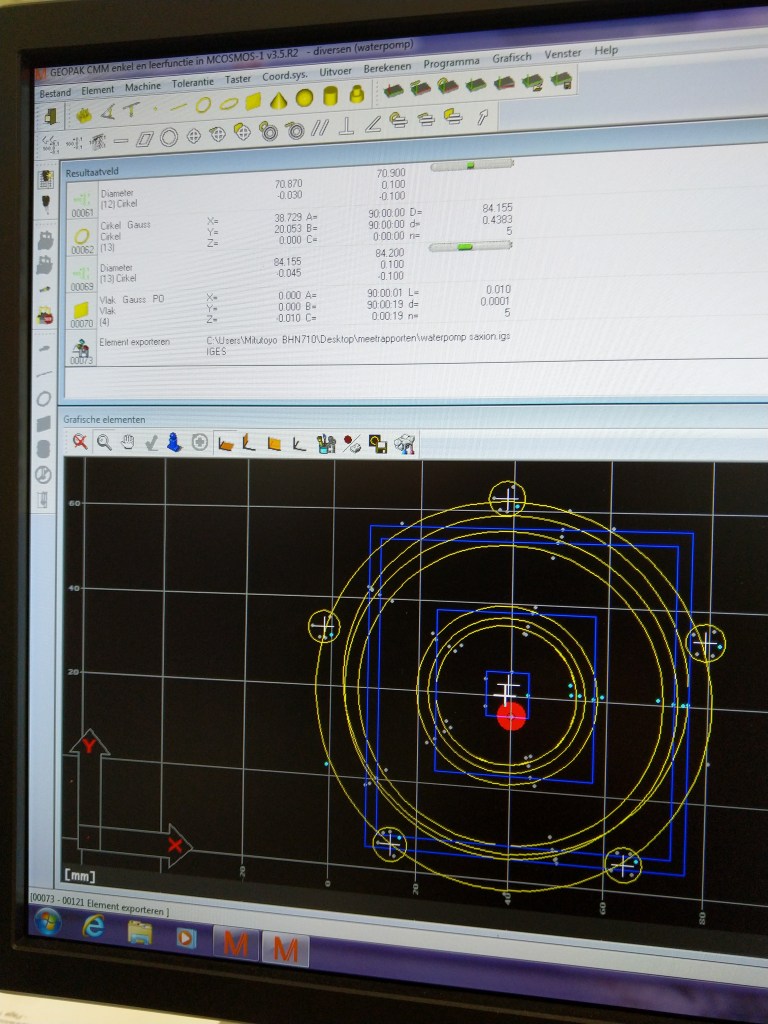

The fit of the shaft and the exact positioning of the holes were measured by Peters FMI.

Digital repair

The 3D model has been checked for errors. 1 mm of material has been added in Autodesk Netfabb to drill out and ream the fit holes.

Preparing for 3D printing

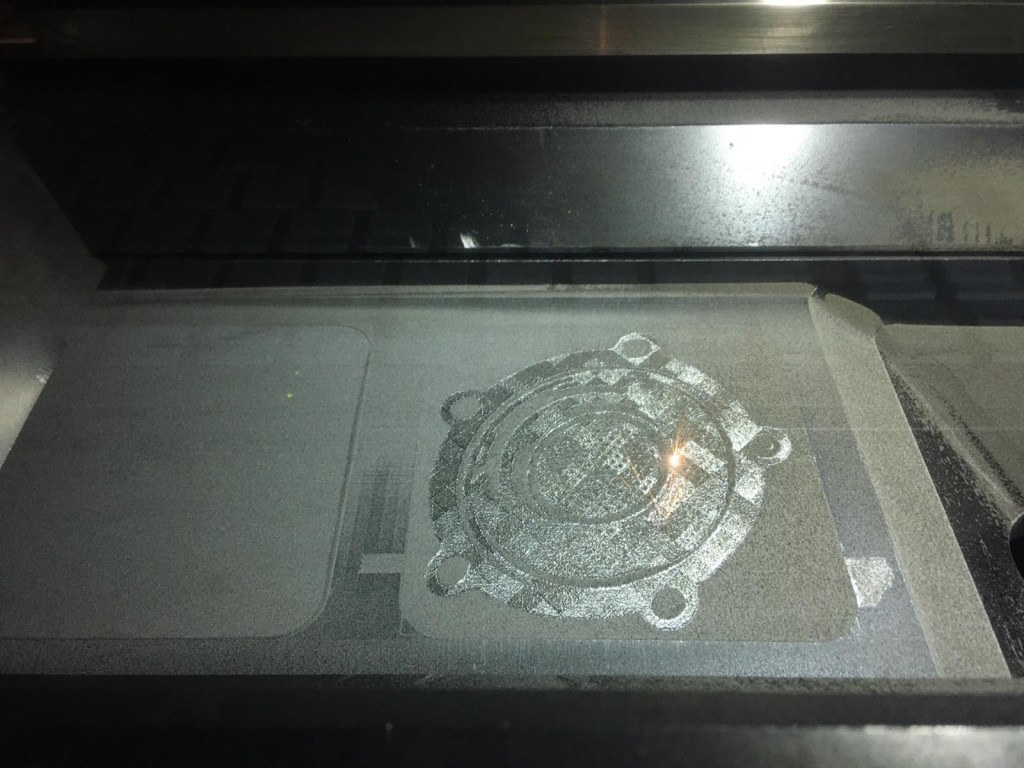

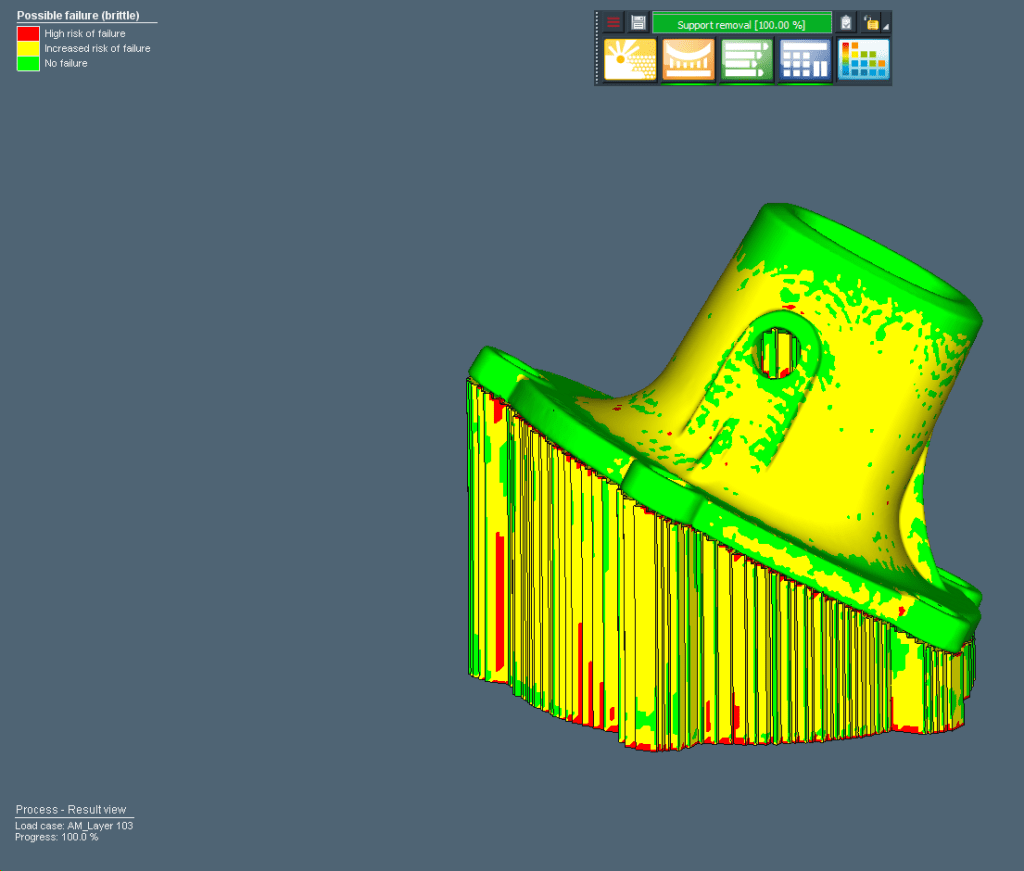

It was decided to print the model in SS316L with the SLM technique, because it is accessible within the research group. The print just does not fit horizontally in the ConceptLaser Mlab Cusing metal printer. In order to be able to print, the print has been placed at an angle. Support material has been added with Materialize Magics.

3D Printing

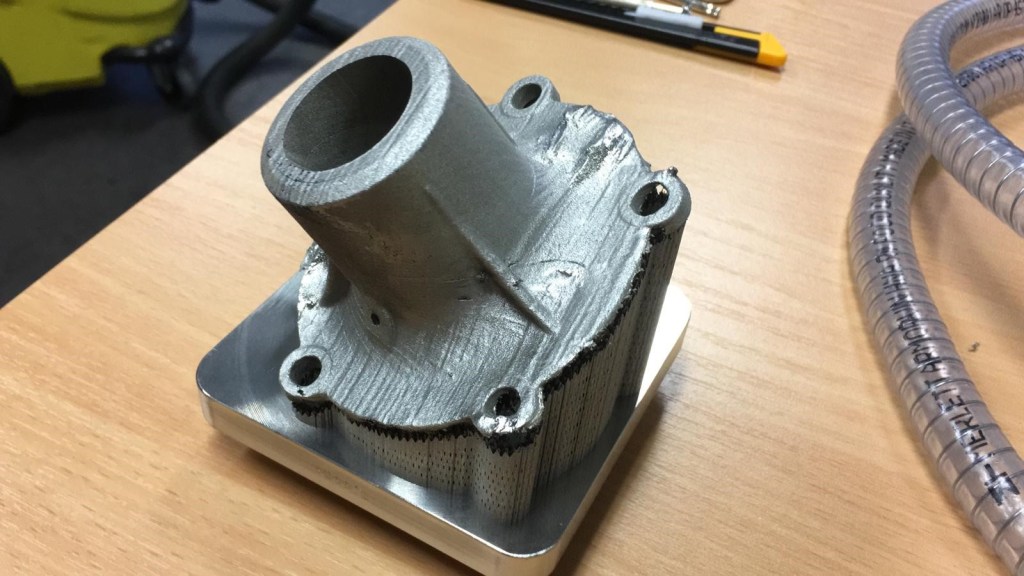

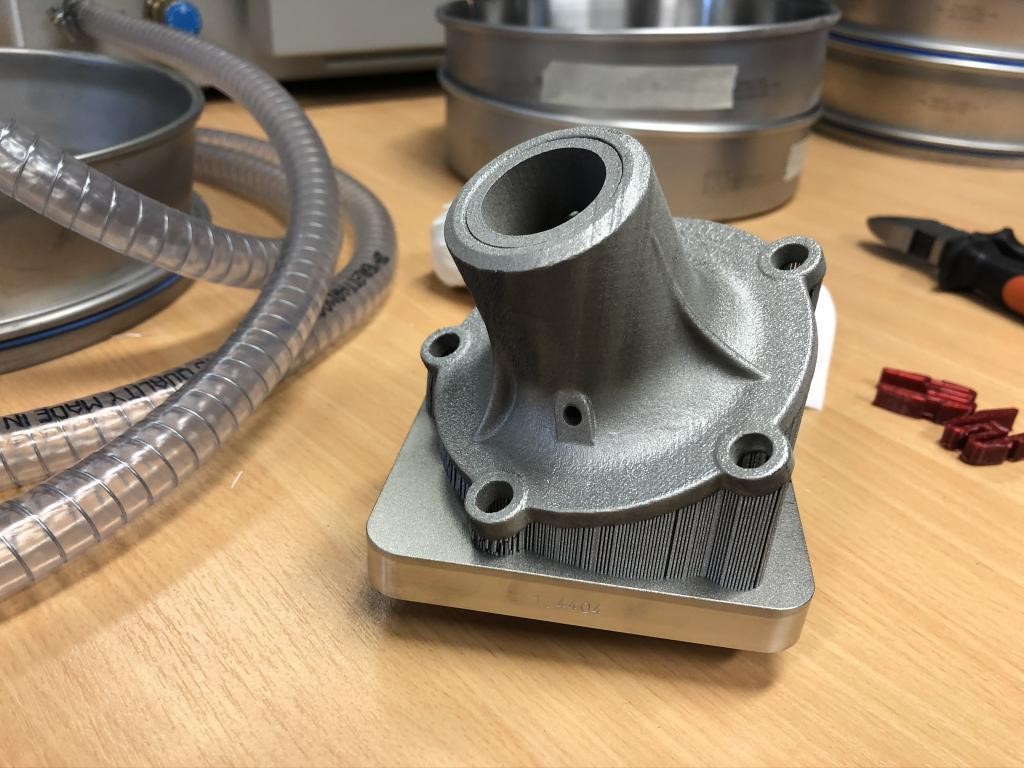

The model is printed on the ConceptLaser Mlab Cusing. Several prints were made until a successful one was achieved.

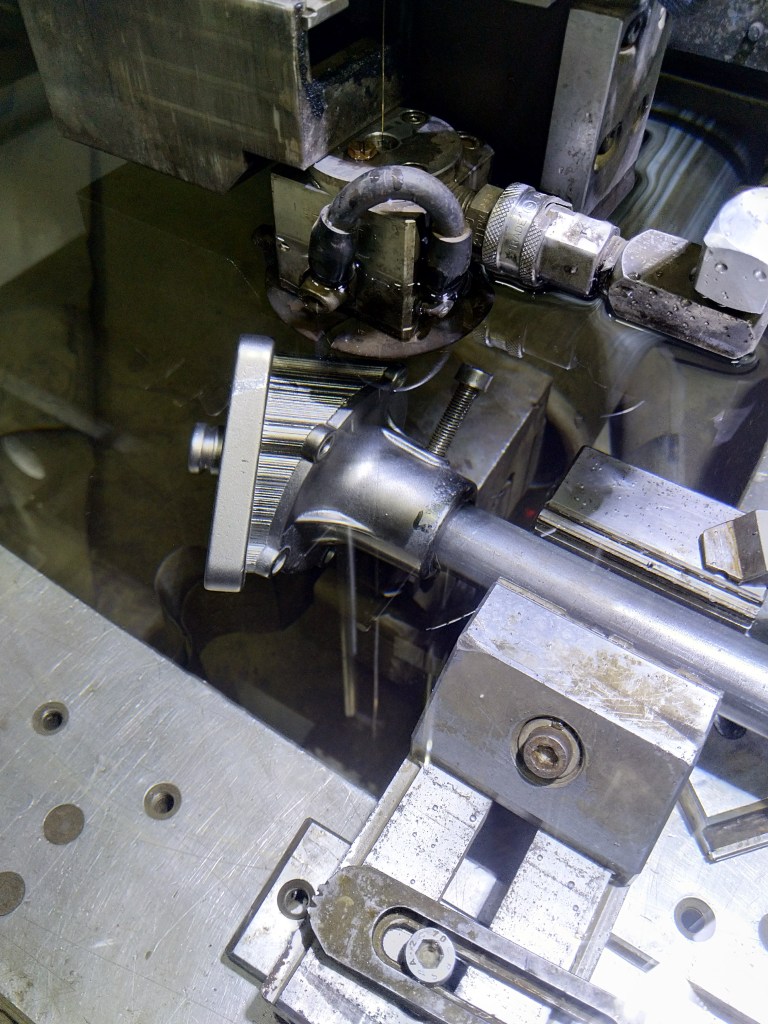

Post-processing

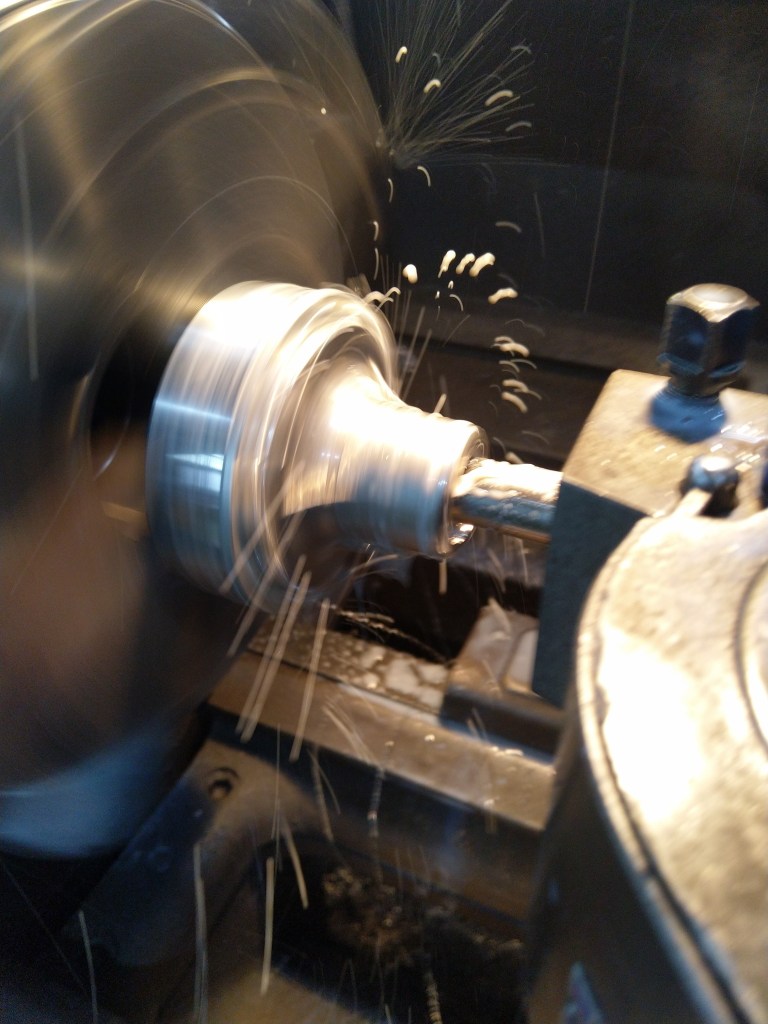

After the powder has been removed, the PCB has been removed from the build plate. This was done at PetersFMI using wire EDM. The remaining support material on the inside was removed with a chisel on a lathe.