Establishing design and production guidelines.

Together with 5 regional partners; Thales, Z-tech, AWL, PM-Aerotec and Aeronamic a research project has been set up for the development and anchoring of knowledge about 3D metal printing.

This is done by means of specific questions coming from the companies through generic technical research and developments of future-proof specific business cases.

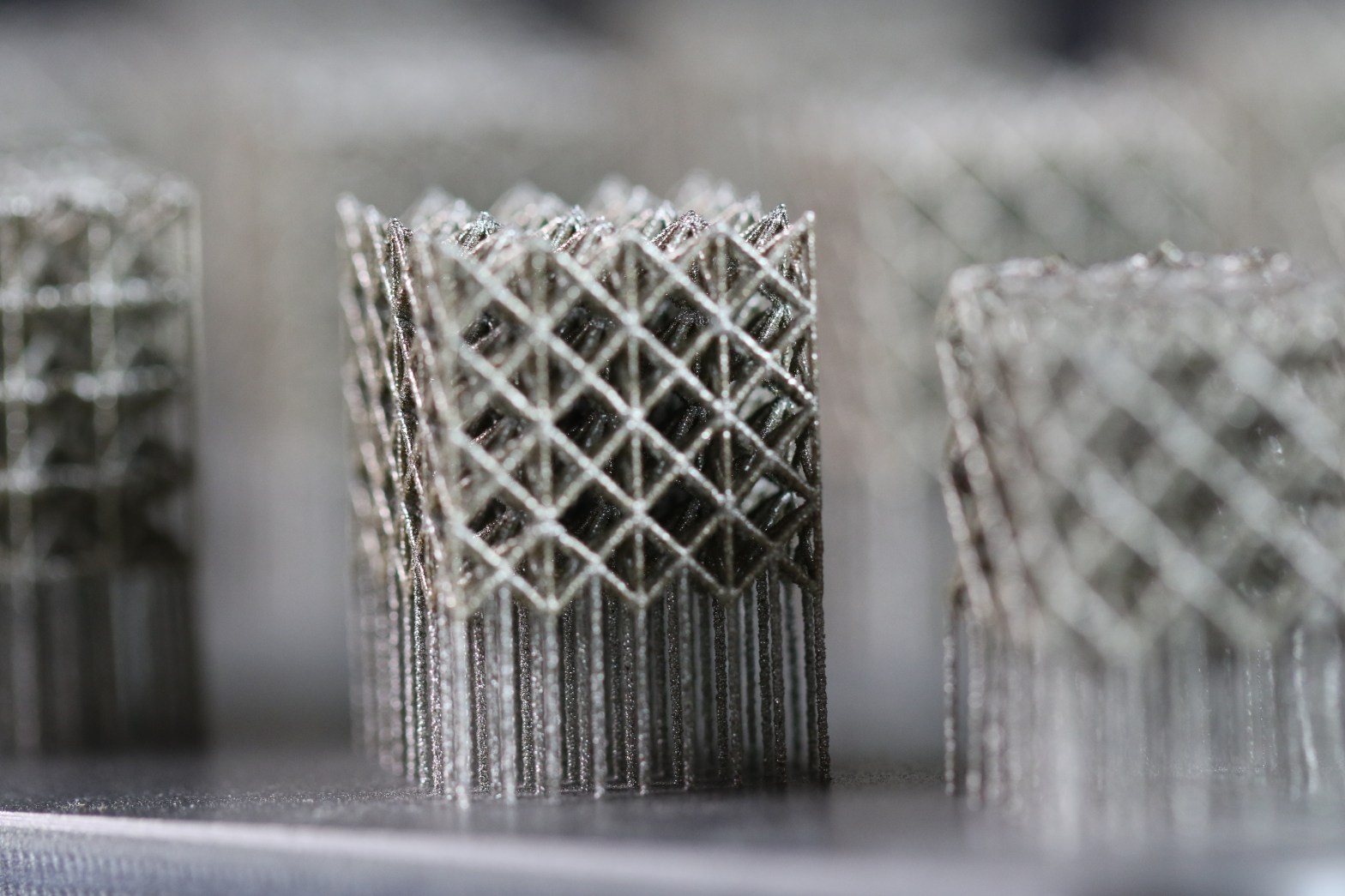

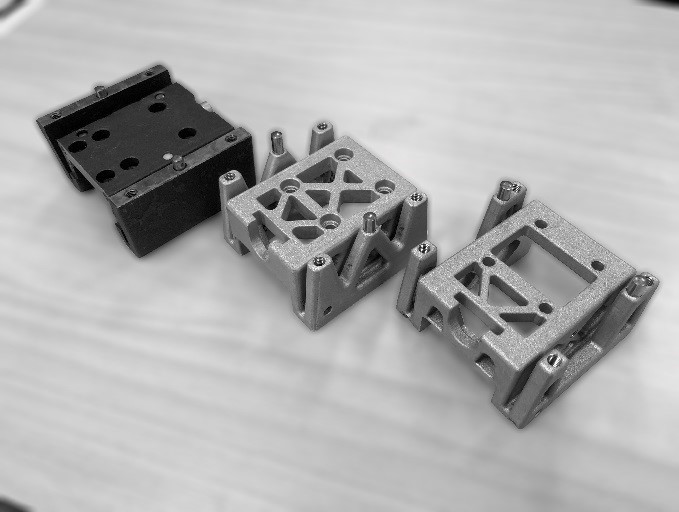

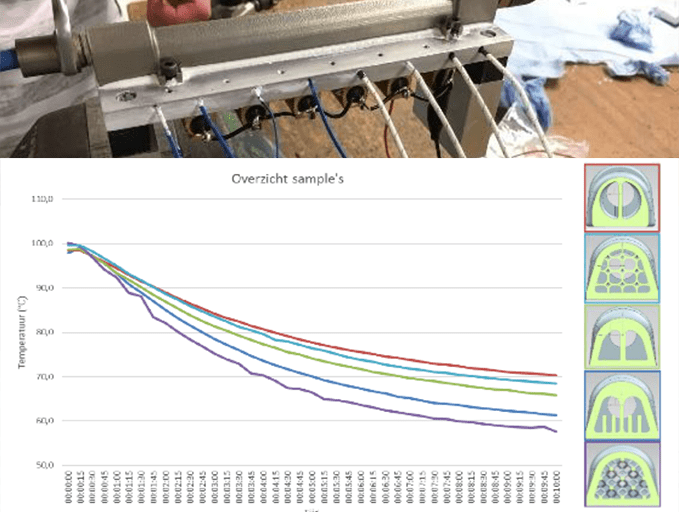

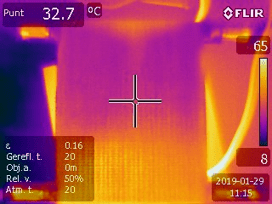

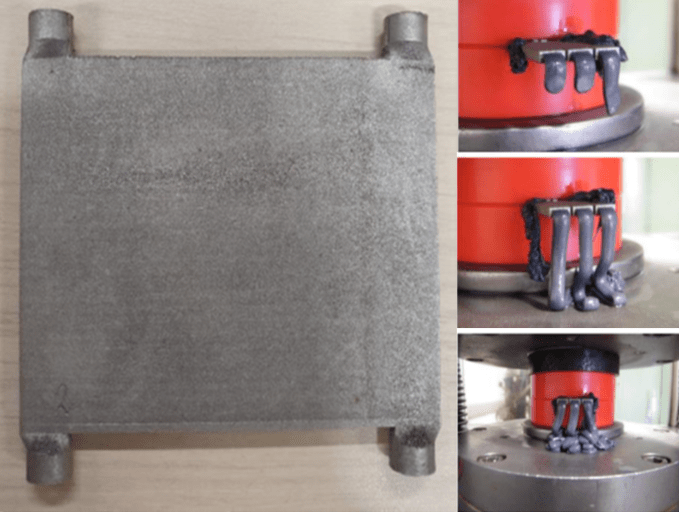

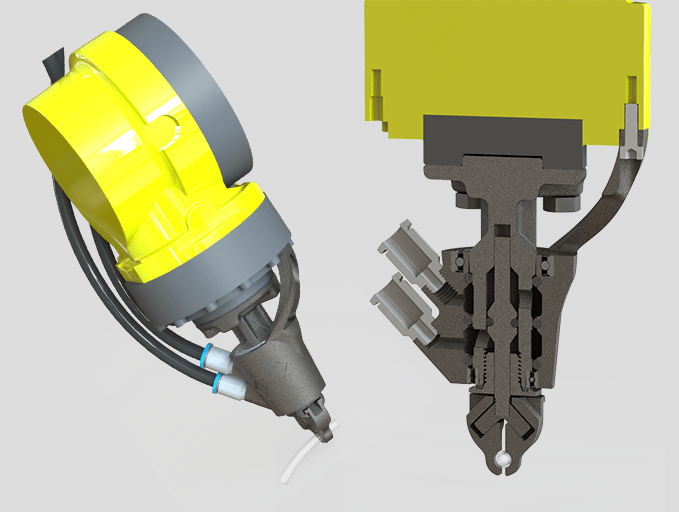

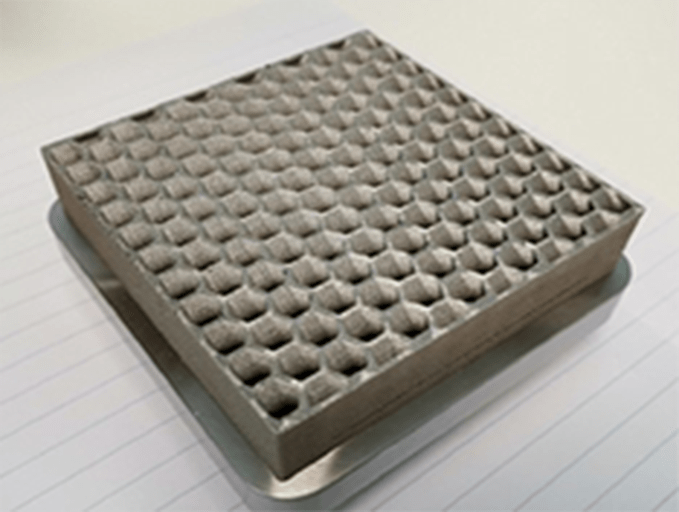

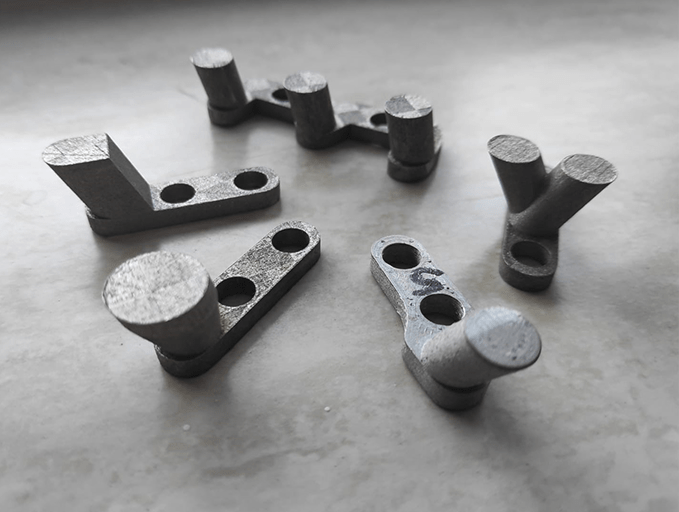

We proceeded by collecting 1 or 2 product cases from each company. The parts suggested are then optimized for 3D metal printing by researchers, designers from the ID research group and students (where possible). Design and production guidelines are established from the cases.

The guidelines give this case-oriented approach a clearly investigative character. Some of the most common desired improvements are: more efficient cooling by AM, post-processing steps, and optimization strategies. In the coming six months, research will be conducted into the influence of the print powder.

Duration: 2018 – 2020

One thought on “Biz 2”