Lever (Oyfo)

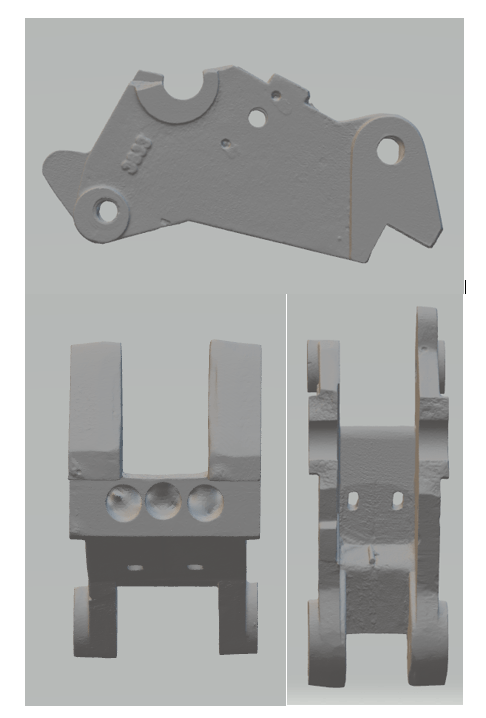

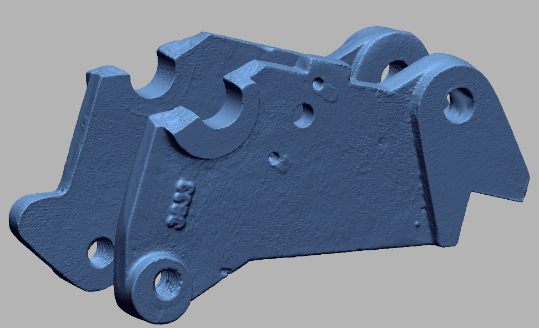

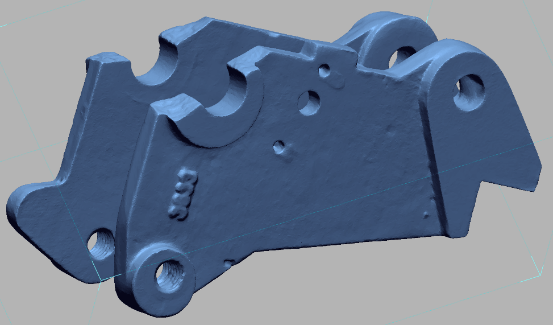

A large switch box is used to convert an electrical circuit with a lever. To minimize sparking, the circuit must be converted quickly. A critical part of this ministry has been broken down. This part was originally a cast part and is no longer in production.

Scanning and modeling

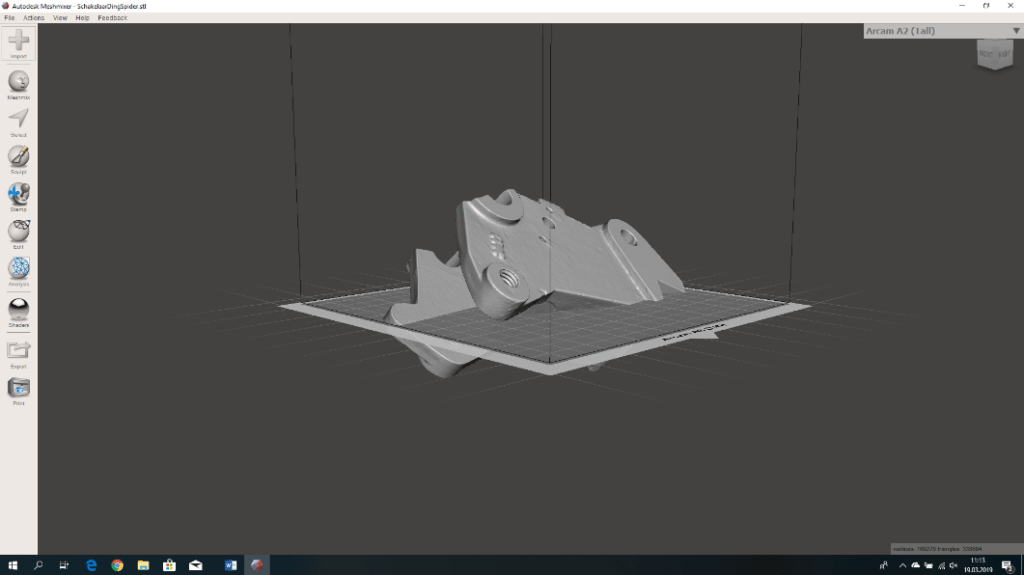

Several scanners were used. The 3D scanner Artec Space Spider gave the most detailed result. Two methods have been attempted for the reconstruction:

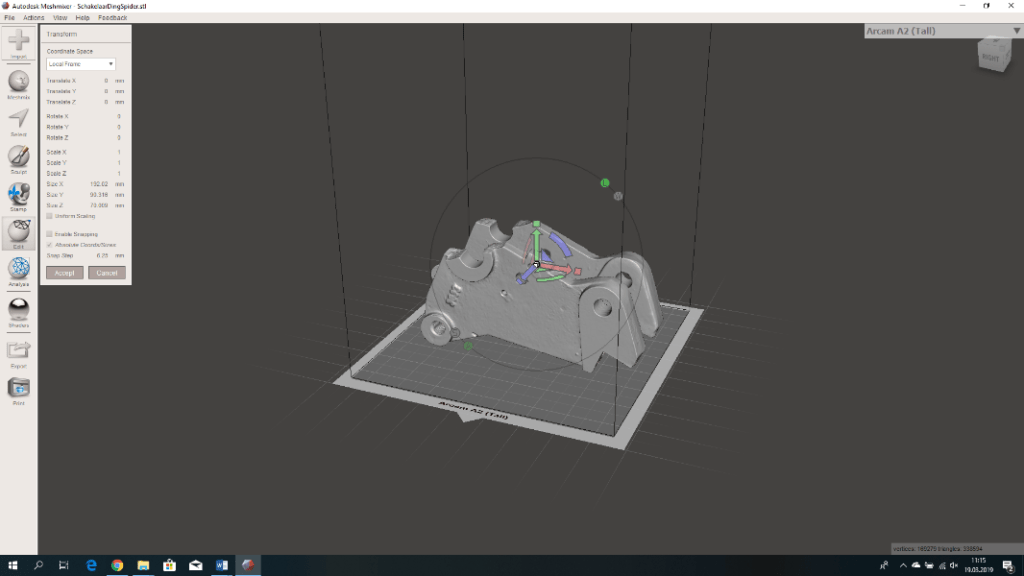

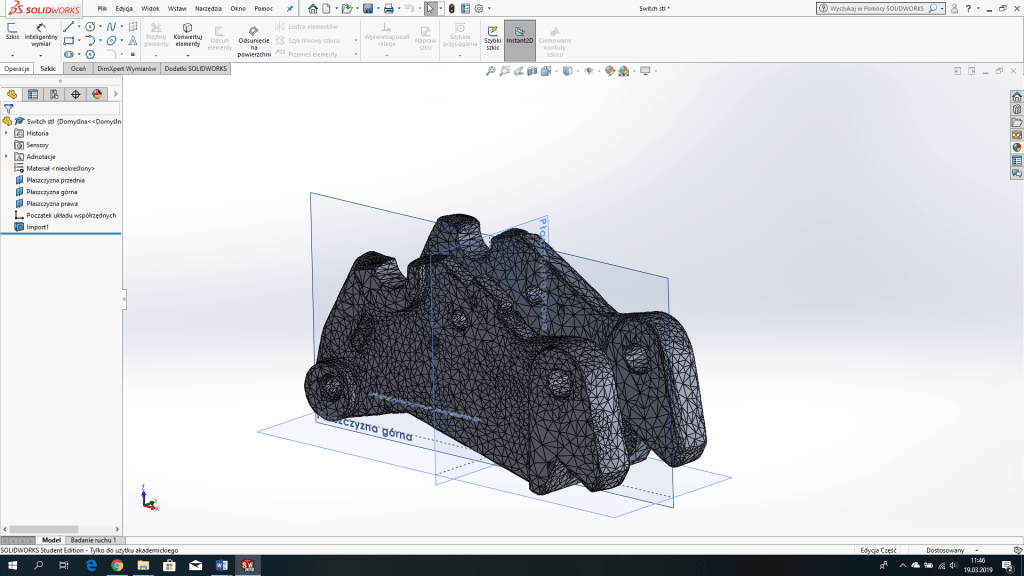

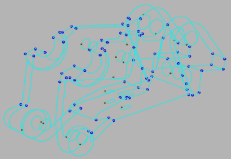

1) Mesh Mixer in combination with SolidWorks:

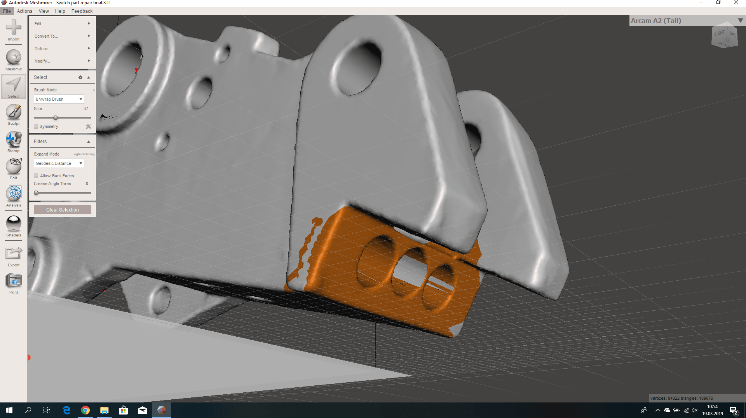

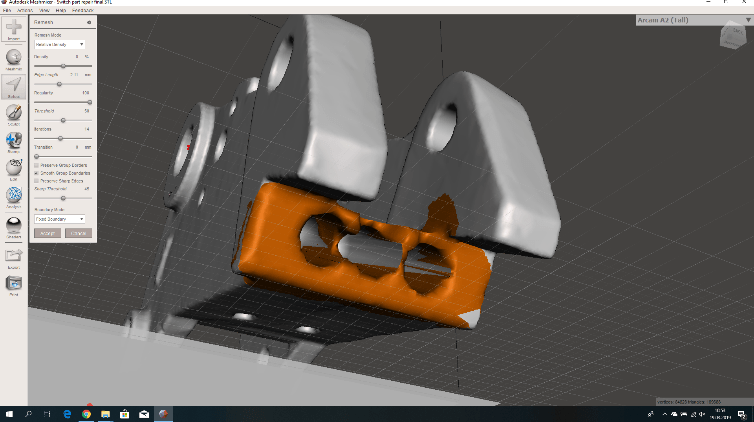

In Meshmixer the scanned object was placed in the correct orientation. The mesh was then reduced (via EDIT> REDUCE) to less than 20,000 polygons and then exported to STL. Now it is possible in SolidWorks or another CAD program to draw the broken part and give the holes the desired size. The object must then be meshed again in Meshmixer, because details may have been lost as shown in the holes in Figure 38. Here the quality of the mesh has been increased locally.

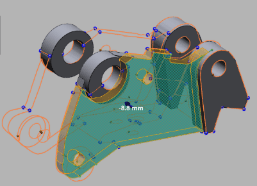

2) Geomagic Design x:

The same type of trajectory was also followed in Geomagic Design X. First of all, the mesh was cleaned up where necessary. Then different segments are created with the auto segmentation function. The program detects the contours that can be traced to a sketch. Then a Solid Body was made on the basis of the sketches and the broken off piece was drawn.

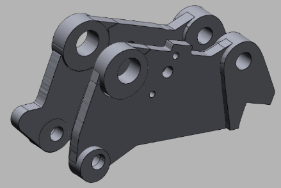

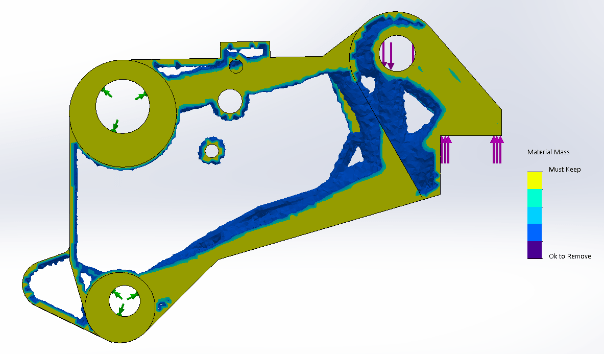

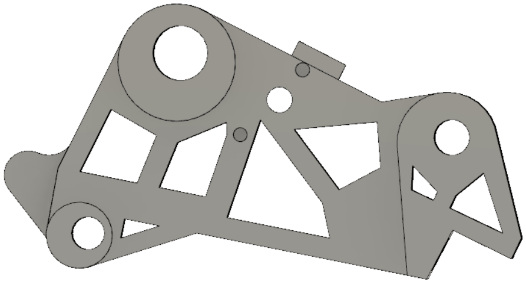

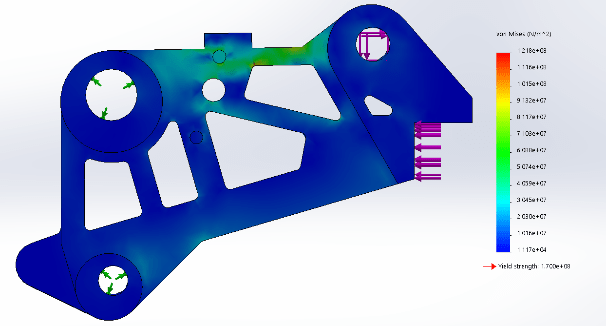

Optimization

There are software packages in which the maximum outer dimensions of your product are indicated (design space) and where which forces apply. Calculations have been made to find out which forces are acting on the part. These are then entered into the software. The software then calculates where material can be saved because low voltages occur there. In theory, this creates the ideal shape to absorb the forces with as little material as possible. In this case, the Fusion 360 program was used for the topological optimization.

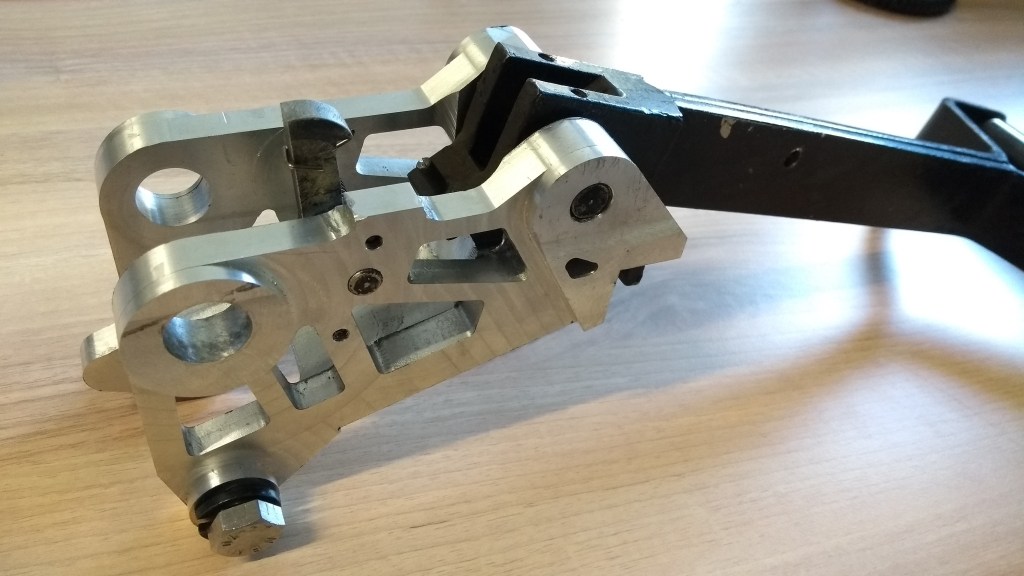

Milling and post-processing

At the start, the idea was to 3D print the redesigned products, but because this part is \too big for our 3D printer, we chose for CNC milling. A CNC program was been written for it. After milling the part, it still contained sharp edges that could be removed by sliding grinding. To provide the part with a color (like the original), it can be anodised. It was first tested at Oyfo whether it fit and functioned.