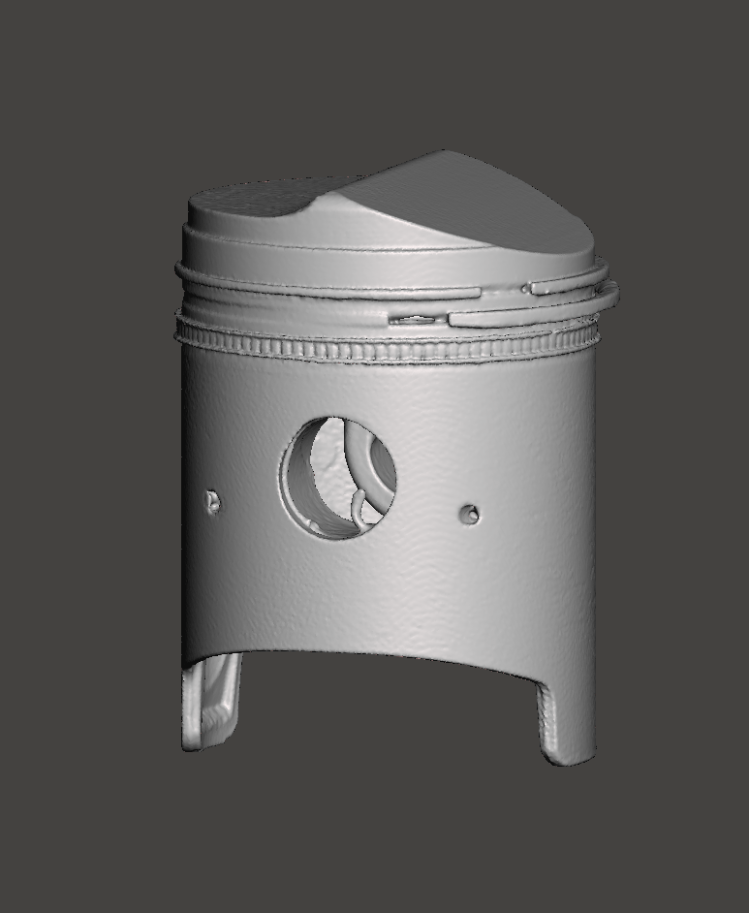

Piston

A piston moves back and forth in a cylinder and has a complex geometry. The piston appears perfectly round, but is slightly tapered to avoid jamming. High demands (thermal, mechanical and dimensional tolerances) are placed on a piston and it is exposed to varying temperatures. Pistons can only be ordered in large quantities, but often no more than 10-20 pieces are needed. All this makes the piston a great case for researching the (im) possibilities of 3D printing.

Intention

The intention is as similar as possible. The specific aluminum alloy is important due to its function in a combustion engine.

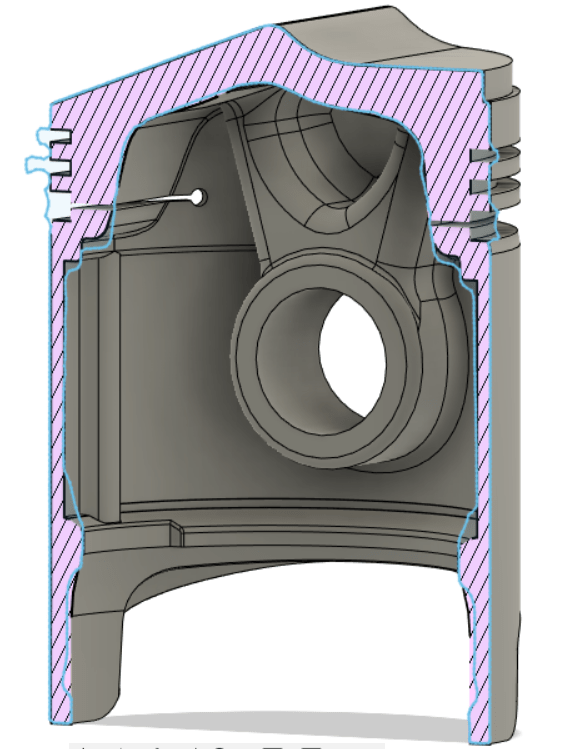

Scanning

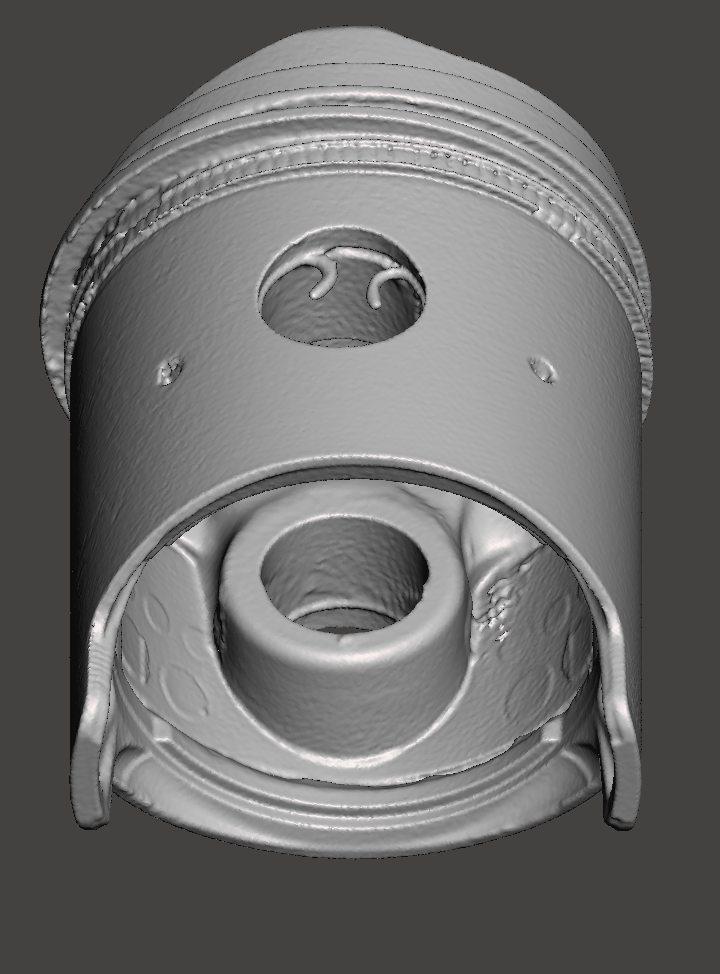

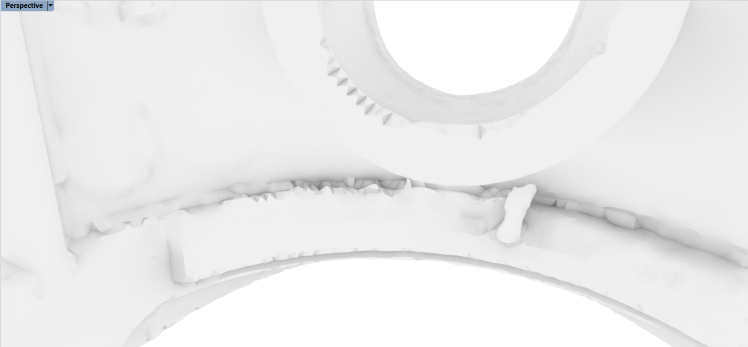

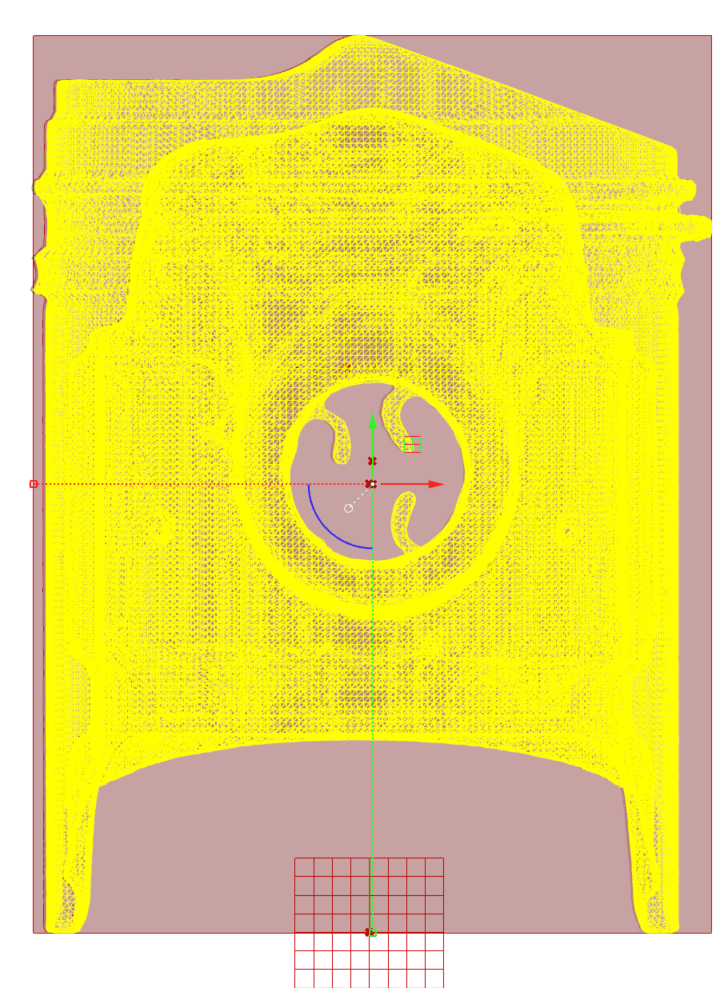

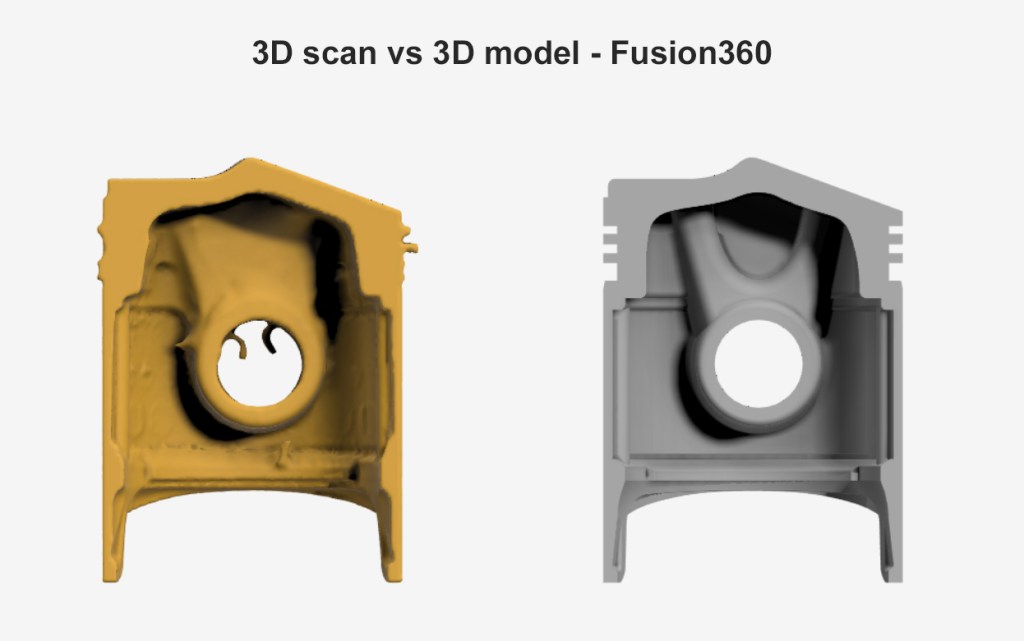

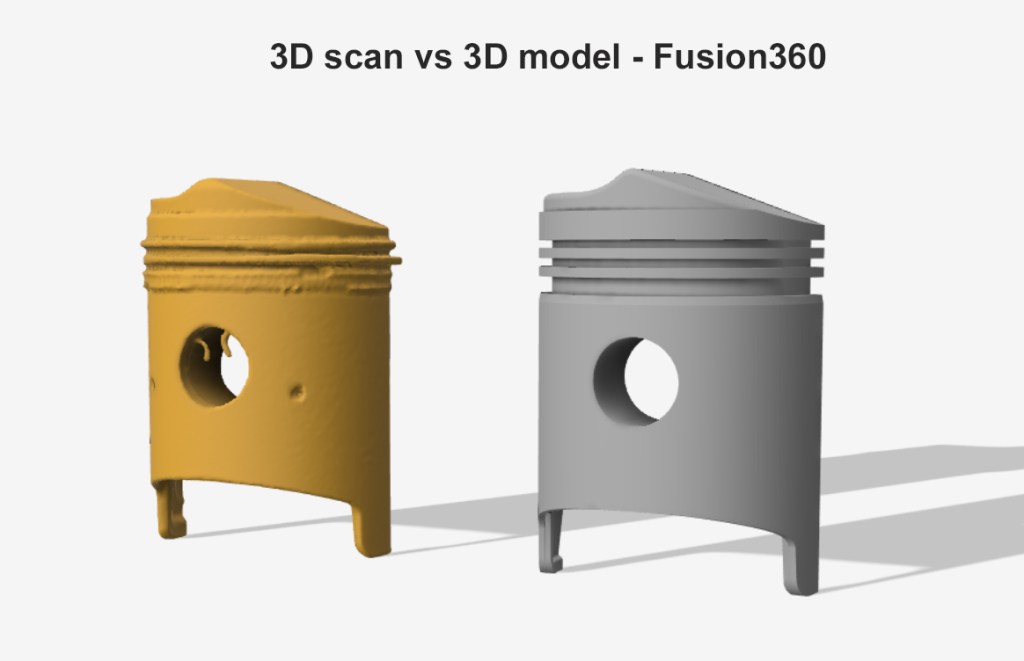

Scanning and measuring on the inside is difficult due to the cavity that is difficult to reach. An option would be to cut the part in half to be able to measure. It was decided to scan the part with the Artecs Spider. During scanning, the piston rings were still on the piston. Due t the complexity of the part, certain geometries were too noisy for the 3D scan to be used directly as 3D modeling reference. To overcome this complication, reference from main cross-sections were used to represent the geometry in Fusion360. In Grashhoper (an addon for Rhino), a tool has been created to compare the scanned and 3D modeled piston on the basis of multiple crossestions spaced at 1mm.

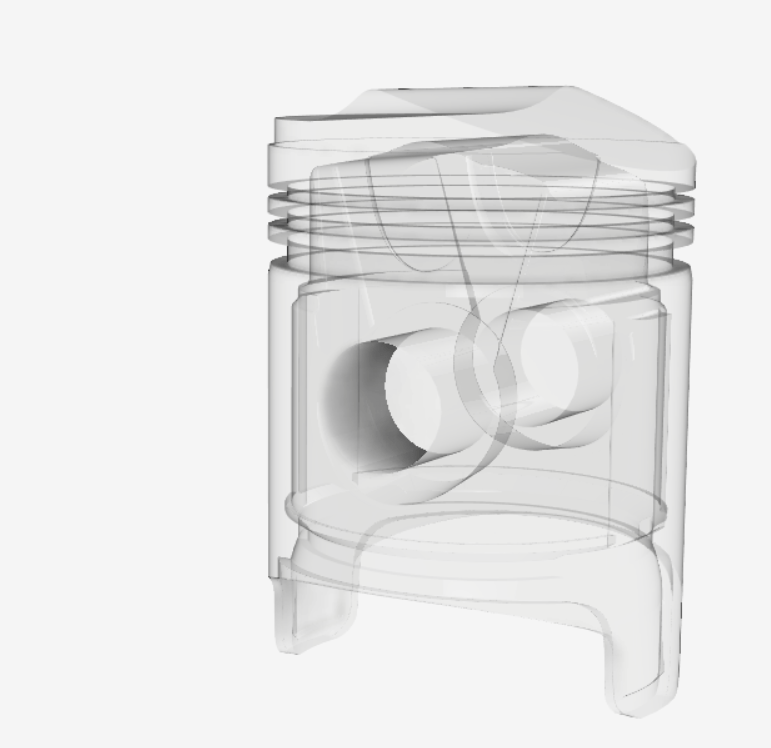

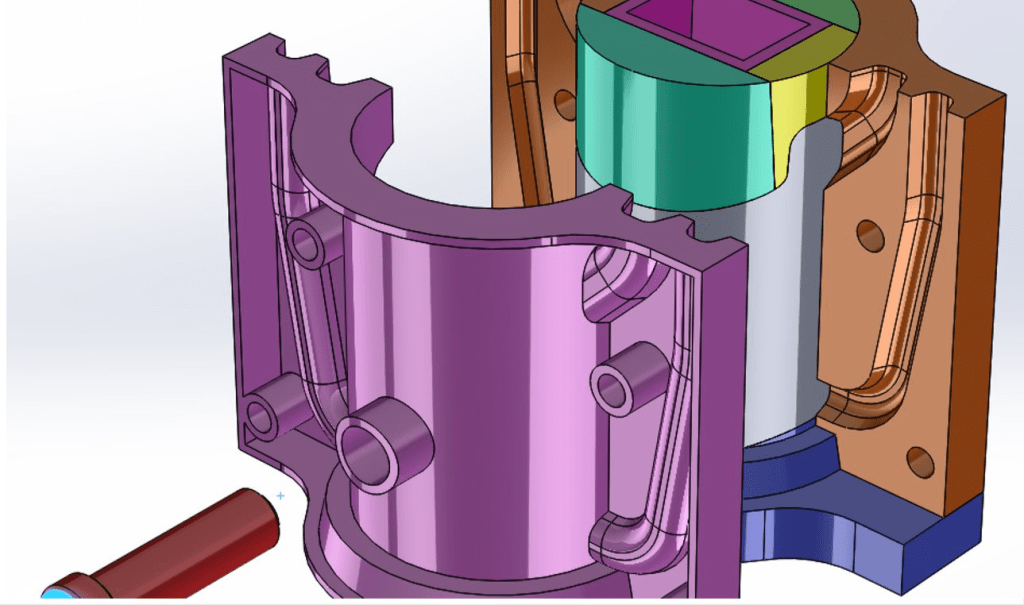

Final model

The final model was adjusted multiple times.

Preparing for 3D printing

Several options have been considered for making the piston.

Option 1: Printing the piston directly, this turned out to be difficult given the specific metal alloy.

Option 2: Metal mold SLM printing and aluminum casting

Option 3: Printing mold with ceramic (DLP process), casting aluminum and smashing mold

Option 4: Printing molds (FDM) for sand molds and sand cores, then casting aluminum. An alternative is to 3D print the sand molds directly.

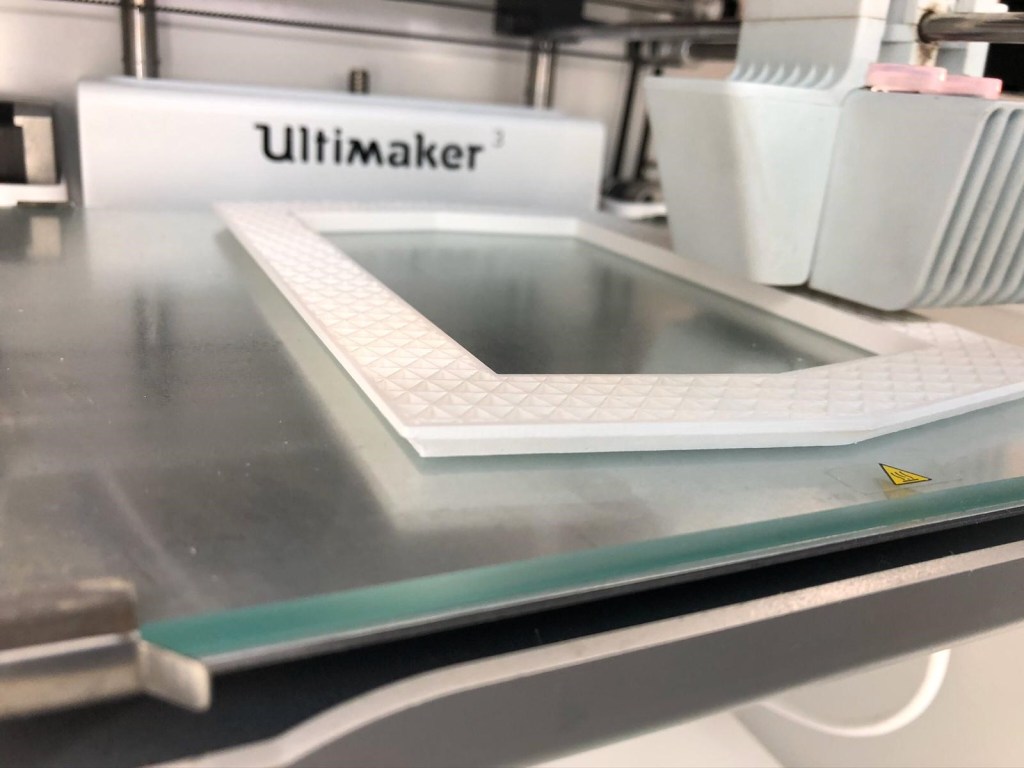

Typically all pistons are replaced during an overhaul, so typically 4, 6 or 8 pistons are needed. Working with molds is therefore desirable. Option 4 with plastic FDM printed molds then costs the least and casting in sand corresponds to the original production method. The molds for the sand molds are modeled on the basis of the 3D model. Subsequently, these FDM were printed with PLA plastic on an Ultimaker.

The final model of the piston and all steps of its production:

Surface post-processing is done by Motoren Revisie Meijerink B.V.