Practical implementation of generative design in the industry

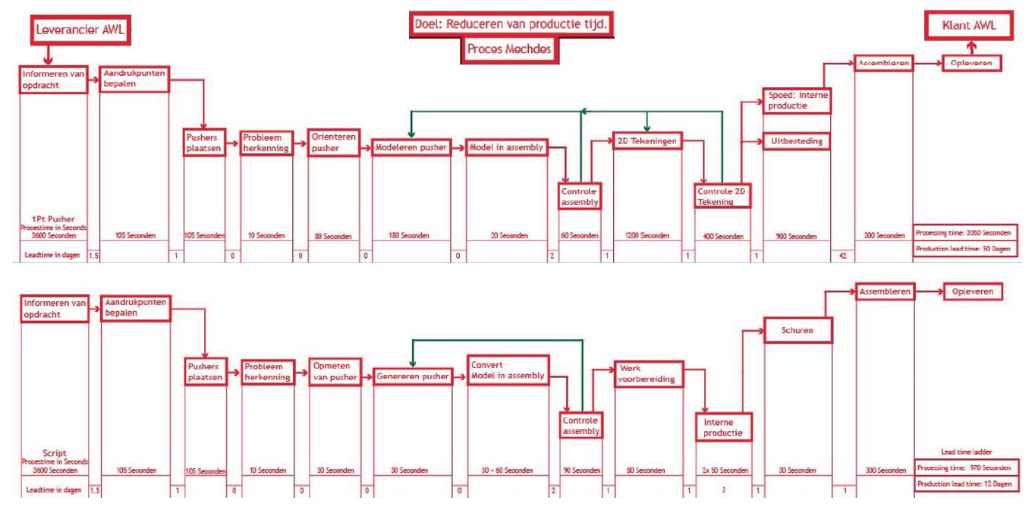

• Goal: The goal of the assignment is to reduce the time it takes to design and produce a non-standard welding jig pusher. This means that the process was monitored from order to delivery of the welding jigs. Here, it is examined whether time and therefore money can be gained if this process is completed by means of 3D printing in combination with generative design.

• Approach: Design process.

• Outcome: An analysis of steps for the current design process and insight into what takes the most time. A grasshopper script with which different variants of a pusher can be modeled quickly.

• Profit for the company: Insight into the added value of 3D metal printing and insight into the added value of parametric design.

Graduation assignment: Fabian Jacobs