Heat pipes (Thales)

• Goal: The ability to produce a custom heat pipe without the limitations of conventional production methods is a great added value for Thales. Within the framework of the project, important knowledge about the possibilities of printing heat pipes has been obtained. However, the research is not finished yet. Thales now has the choice to continue the research itself or to collaborate with the next project group. In any case, Thales has acquired valuable knowledge so far.

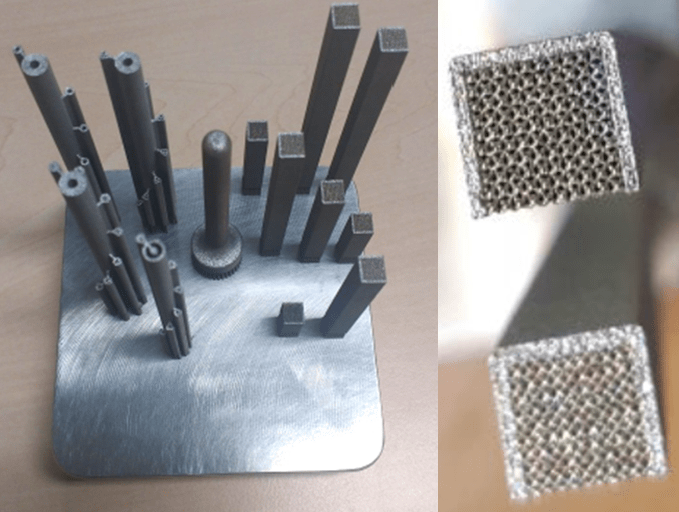

• Approach: literature research, theoretical design of a heat pipe with internal wick structure, printing and testing of 3D printed wick structure.

• Outcome: Design, printing and testing of the wick structures yielded good results, the ordered octahedral 500 μm Unit cells with a rib diameter of 125 μm, recommended by the literature, function sufficiently.

• Profit for the company: Knowledge about the possibilities to fabricate wick structures in heat pipes using 3D metal printing.