Hybride prints (PM Bearings)

Satge 1:

• Purpose: Printing a linear guide with teeth, by printing a teeth made of stainless steel 316L on an existing linear guide made of stainless steel 420.

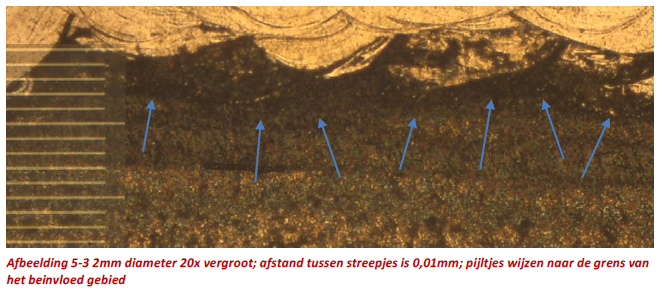

• Approach: Pilot research: printing a stainless steel 316L tie rod on an existing RVS420 guide, breaking it on a tensile testing machine, and afterwards microscopically examining what the weld and fracture look like.

• Result: Printing of RVS316L on existing RVS420 is possible, the adhesion is good. The weld between both materials does not break, but the tie rod does. The positioning of the design on the existing part does require some skill and experience from the operator.

• Profit for the company: Insight into the new possibilities that hybrid 3D metal printing can bring in production.

Stage 2:

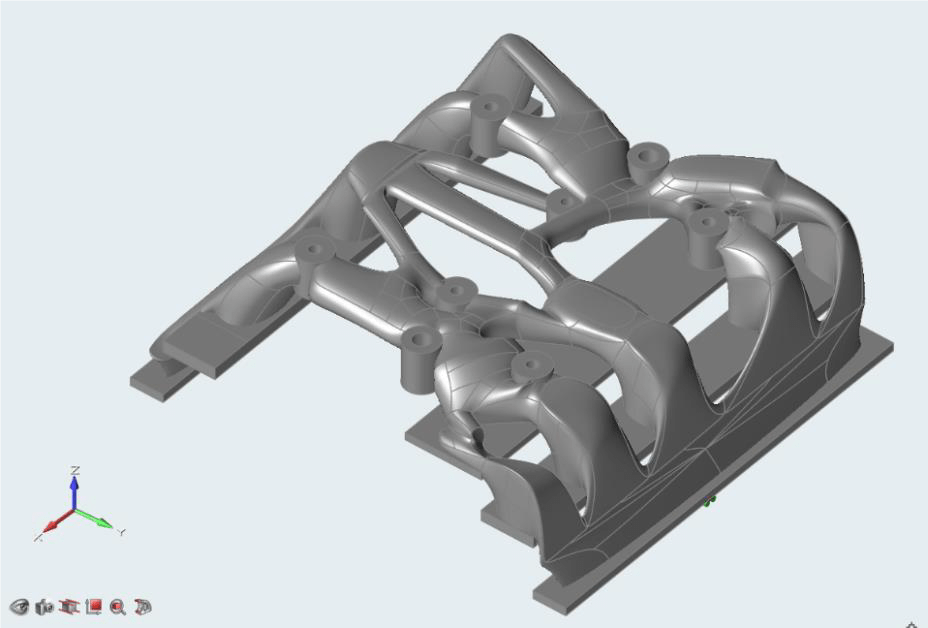

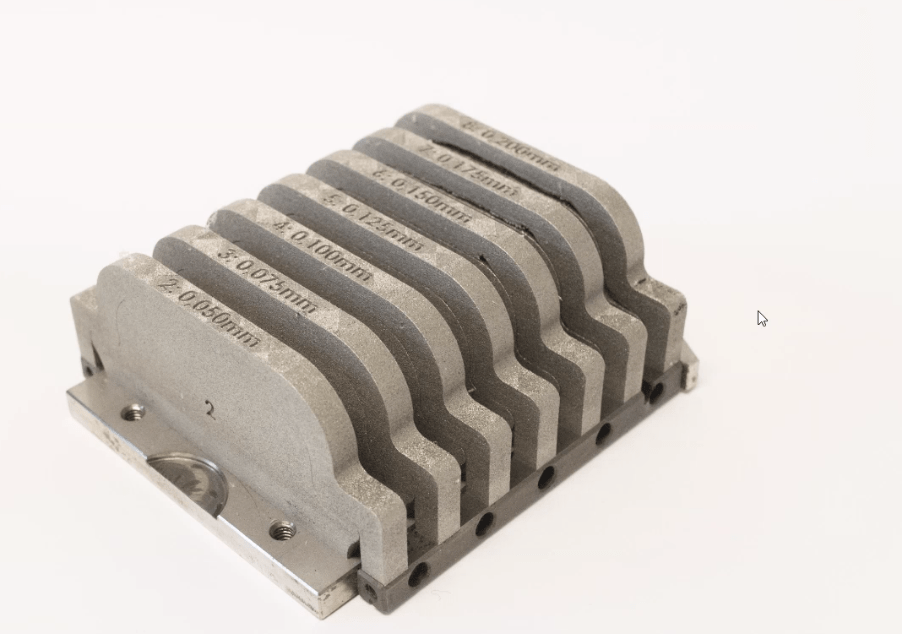

• Goal: Design and print a bridge (strong, rigid and light) of a distance between RSD2075 linear bearing sets.

• Approach: preliminary research into linear conductors, bridging designs, topological optimization

• Outcome: It is quite possible to design a topologically optimized table part with various integrated functions in it to move between 2 guides of the RSD2075 bearing set. Corrosion formed in the hybrid print.

• Profit for the company: Insight into the possibilities and limitations of 3D metal printing and hybrid printing.