Optimal heat treatment (Pontus)

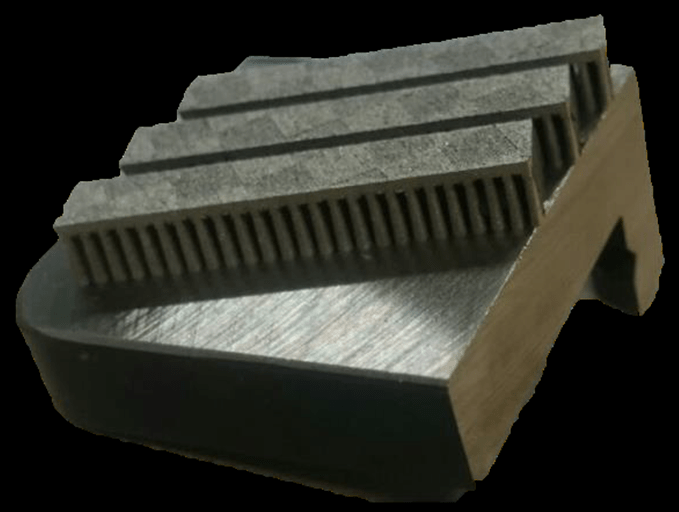

• Goal: To determine the most suitable temperature and the time required for the heat treatment of the 3D metal printed product. Determining the deformation of the 3D metal printed product according to the design guidelines after the heat treatment.

• Approach: print samples, have samples undergo various heat treatments (temperature 450 ° C and 1050 ° C, and time 0 to 6 hours), measure deformation

• Outcome: Annealing helps to reduce stress in printed products. Annealing of parts for 6 hours at 450 ° C ensures higher accuracy of these products.

• Profit for the company: Insight into the possibilities to improve the quality of 3D printing with the help of annealing.