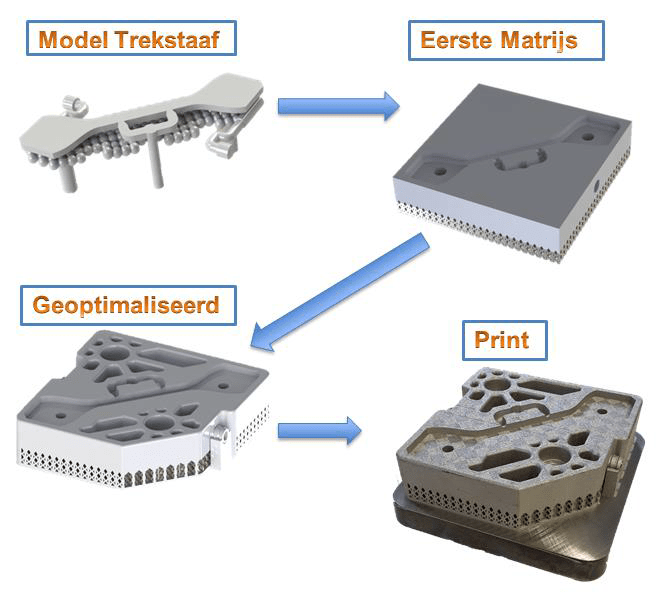

Physically printed optimal mold (Protype)

• Purpose: To determine how flat and smooth a mold can be printed (without finishing operations).

• Approach: redesign mold, print mold, testing

• Result: We succeeded in printing an optimized mold with a complex cooling channel and a pillar textile that is only possible with 3D printing. However, the print is not printed without errors. The wings are not printed properly and there are two stripes across the mold due to damage to the wiper. The roughness is also high and there is a slight deviation in the height of the mold. To fix these errors, post-processing may need to be done. Because the mold has not yet been tested, it cannot be concluded whether the mold works and which post-processing operations are or are not required

• Profit for the company: Insight into the possibilities and limitations of 3D metal printing for mold printing.