Smallest fluid channels (PM Bearings)

• Objective: To investigate the smallest possible hole diameter that can be printed in a PECM tool (precision tool with very small fluid channels, Precision Electro Chemical Machining).

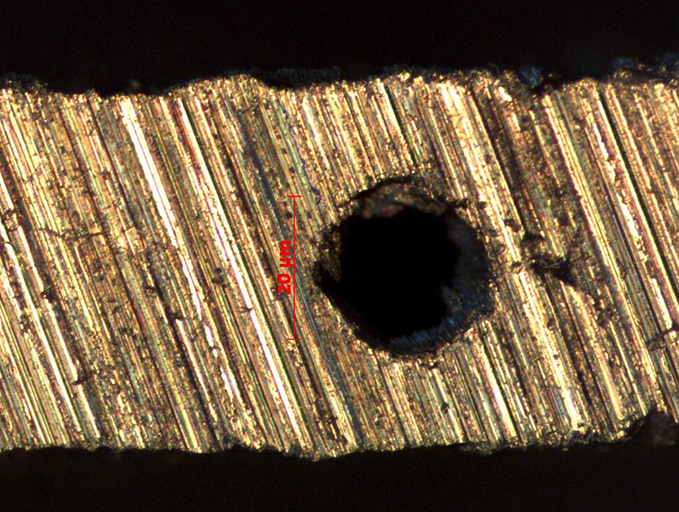

• Approach: Print multiple samples containing various channels (0.2 mm, 0.3 mm, 0.4 mm) and wall thicknesses, cut samples and examine them microscopically.

• Outcome: The smallest possible fluid channel that produces a positive print result with the Mlab cusing is in the vicinity of the 0.3 mm diameter.

• Profit for the company: Insight into the possibilities and limitations of 3D metal printing when producing small holes in a PECM tool.